-

$30.00≥2000 Square Meter

Business type:Manufacturer,Trade Company,Distributor/Wholesaler

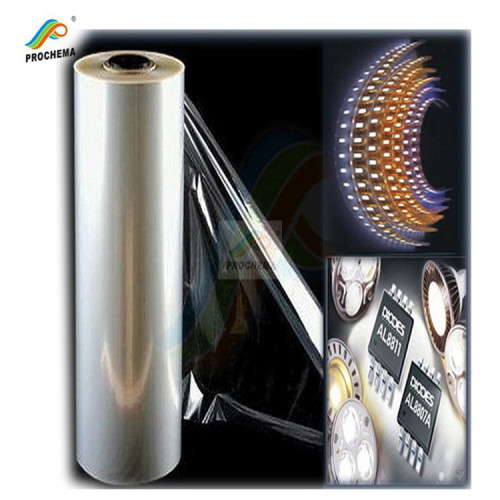

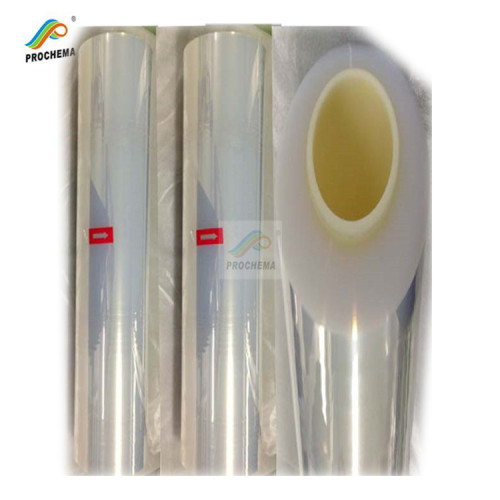

ETFE anticorrosive insulation film for LED releasing

ETFE film is made by imported advanced machine with tape-casthing method.perfect high temperature resistance. It can work long under 150℃ . Speical chemical stability,non-stick, lubricating ,dielectric ,aging resistance and low friction.

It is suitable for the high performance requirements of the aircraft wall and other carbon firber forming isolation . flexible solar cell encapsulation ,FPC releasing encapsulation, Membrane structure and Agriculture greenhouse etc. We offer

Using fluoroplastic film can simplify the back-end processing technology ,improve proudcts quality.

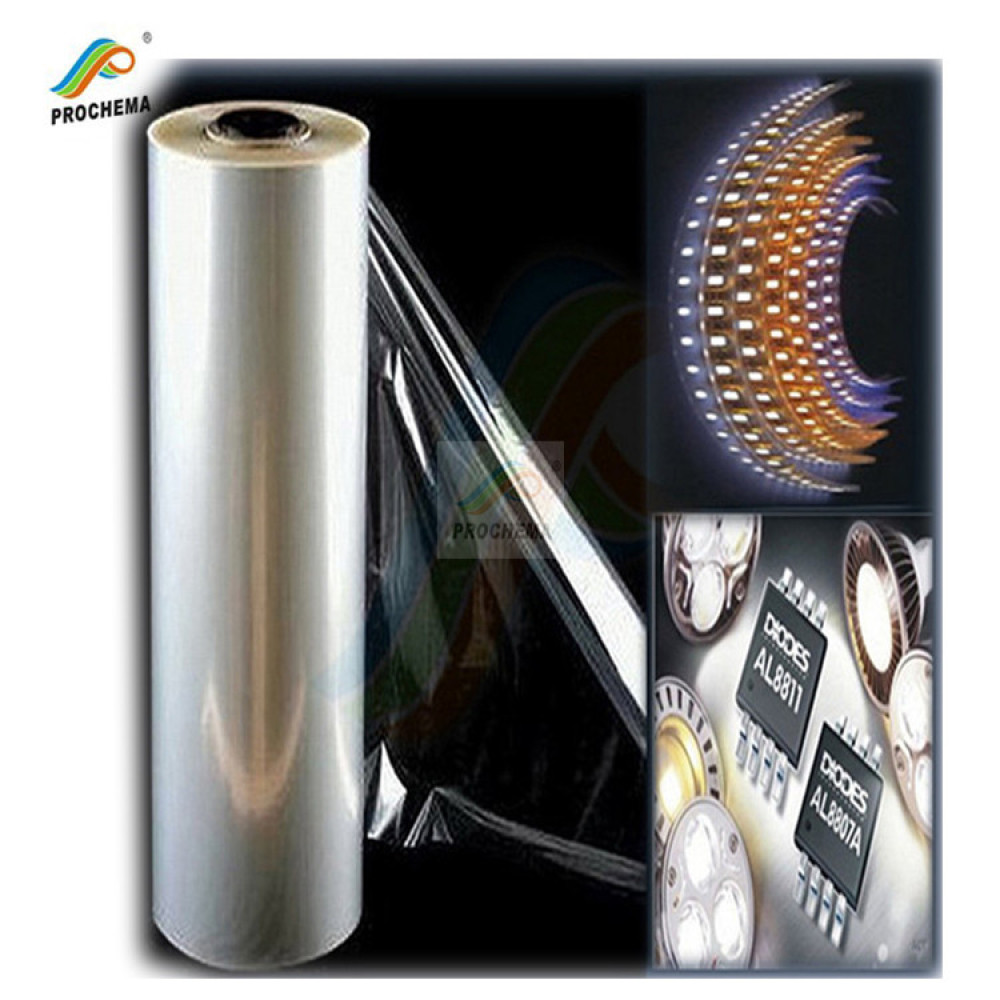

ETFE fluorine plastic film with excellent chemical stability, heat resistance, not sticky, lubricity, pervious to light, light,

electric insulation, weather resistance and self-cleaning, aging resistance, light and low grinding.ETFE film has many excellent properties and used in many fields. Weather Resistance -- Used in 150 ℃ -180 ℃ Chemical Resistance -- Tolerance outside all kinds of harsh conditions Not sticky -- After mold, product surface bright and clean and no pollution

ETFE FILM is recognized as the release FILM commonly used in semiconductor packaging process. Film assisted forming (FAM) is a key process in modern integrated circuit manufacturing. Fluoropolymer films are used to increase output and machine productivity by reducing the peeling force required to remove the IC from the mold and eliminating the need to inspect or clean the mold between injection molding.

Properties:

1:non-stick -- Smooth surface, won't stick to any thing. Low surface energy, resistance to sand, dirt and other pollution.

2:corrosion resistant ---Won't be effected by any strong acids,alkali,oxidizers or almost solvents.

3:high/low temperature resistance: -100℃ to 150℃

4:High diaphaneity

5.Fireproof-- Ignition resistance UL94 Vo

6.abrasive resistance:--0.05

7.Aging resistance : More than 20-30 years long life outside .

8.Weather Resistance——UV resistance, stable mechanical properties after exposure outdoors over 20~30 years.

9.Light Transmittance——Superior transparency, flexible and lightweight over glass.

Application:

LED releasing

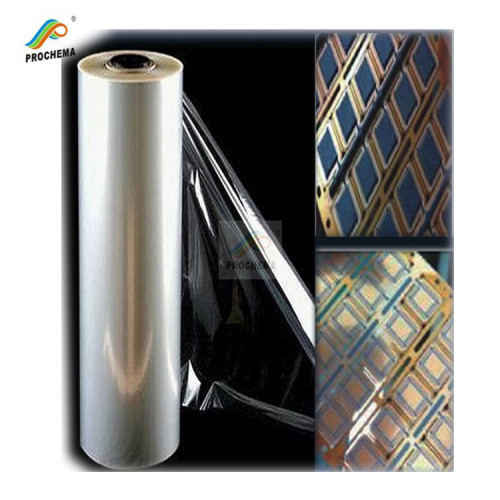

Carbon fiber releasing

Specification:

|

Grade

|

Thickness (um)

|

Width (mm)

|

Weight kg/roll

|

Length (m)

|

Length tolerance (mm)

|

Color

|

Surface condition

|

|

25C

|

25

|

1250

|

54.7

|

1000

|

+5,-0

|

transparent

|

Glossy/Matt

|

|

50C

|

50

|

1250

|

54.7

|

500

|

+5,-0

|

transparent

|

Glossy/Matt

|

|

75C

|

75

|

1250

|

19.2

|

300

|

+5,-0

|

transparent

|

Glossy/Matt

|

|

100C

|

100

|

1250

|

54.7

|

250

|

+5,-0

|

transparent

|

Glossy/Matt

|

|

150C

|

150

|

1250

|

65

|

200

|

+5,-0

|

transparent

|

Glossy/Matt

|

|

200C

|

200

|

1250

|

65

|

150

|

+5,-0

|

transparent

|

Glossy/Matt

|

|

250C

|

250

|

1250

|

54.7

|

100

|

+5,-0

|

transparent

|

Glossy/Matt

|

Technical data

|

No. |

Item |

Unit |

Technical data |

Test data |

|

1 |

Density |

g/cm3 |

1.75 |

ASTMD792 |

|

2 |

Melting point |

℃ |

260±10 |

DSC |

|

3 |

Heat shrink ratio |

% |

TD≤±5 |

Sample:100mm*100mm, |

|

MD≤±5 |

||||

|

4 |

Elongation at break |

% |

TD>200 |

ASTMD638 |

|

MD>200 |

||||

|

5 |

Tensile strength |

MPa |

TD>39.2 |

ASTMD638 |

|

MD>39.2 |

||||

|

6 |

· Flammability

|

|

V-0 |

UL-94 |

|

7 |

Top working temperature |

℃ |

150 |

|

|

8 |

light transmittance |

% |

≥91% |

ASTMD570 |

|

9 |

drug-fast |

|

excellent |

ASTMD543 |

|

10 |

Grind arenaceous value |

Ra |

1.5±1 |

DIN4768-1 |

Q: What's your supportive policy for distributors in overseas market?

A:We support in many aspects including marketing, promotion, product developmentimprovements