Business type:Manufacturer,Trade Company,Distributor/Wholesaler

The strongest fluorine plastic material ETFE film

ETFE Film For Construction Energy Chemical Electronics Pharmaceutical

Now can be widely used in construction, energy, chemical, electronic, pharmaceutical, food and other industries

First, the field of architecture

In recent years, ETFE membrane has been the most prominent application in the field of architecture. Compared with common transparent building materials such as glass, ETFE film has higher light transmittance, thinner thickness, better deformation absorption capacity, stronger impact resistance and self-cleaning ability.

As a result, ETFE is increasingly used on roofs and walls. ETFE can be found in shopping centers, educational and cultural centers, large football stadiums, and even airports and bus stations in the transportation sector. Membrane thickness 200um and 250um is OK.

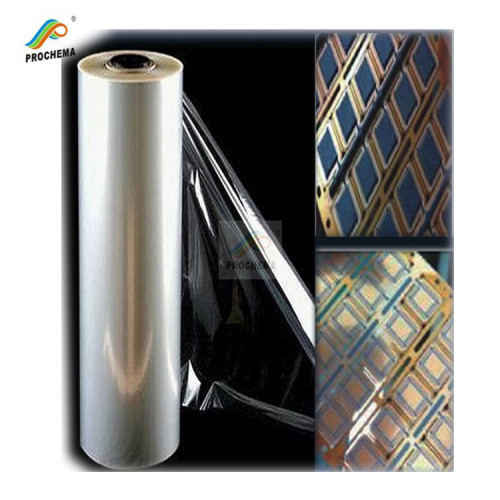

2. Energy

The application of ETFE film in solar panel surface packaging is one of the most promising applications in recent years. Compared with most photovoltaic backplanes on the market that use PVDF and PVF as the outer fluorine film, ETFE has better weather resistance, heat resistance, scratch resistance and hydrophobicity, making it a more ideal photovoltaic backplane material.

ETFE film has begun to be used in flexible photovoltaic cell packaging materials, get rid of tempered glass, the module consists of five layers: upper ETFE film, EVA layer, battery layer, EVA layer, and lower ETFE. The thickness of the battery is less than 1mm, and the weight is only 1KG/ square meter, which truly realizes the flexibility and portability.

In the future, photovoltaic energy storage will be rapidly applied in many scenarios with high requirements for lightweight, portability and application, such as RV, outdoor activities and disaster emergency, and ETFE materials will also open up more application scenarios.

Thickness :25-50um , 75um 100um (usually 25-50um)

Third, the greenhouse field (200-250um)

There are two main types of greenhouses built with ETFE membrane structure, one is agricultural greenhouses, the other is botanical garden/zoo.

ETFE membrane structure agricultural greenhouse

ETFE film was initially used as an agricultural greenhouse covering material. Because of its all-band optical fiber transmittance, it is especially conducive to the infrared absorption of plants, offset the low radiation temperature at night, and conducive to the growth of crops. In Japan, almost all planting greenhouses will use ETFE film, which shows its wide application.

ETFE Membrane Structure Botanical Garden/Zoo

Such applications are mainly the creation of tropical botanical gardens or plant research bases in areas unsuitable for tropical plants, and the raising of tropical animals in cold places. This kind of ETFE greenhouse has high requirements for lighting and insulation, and the service life of the building is also permanent (more than 25 years), such as the Garden of Eden in England.

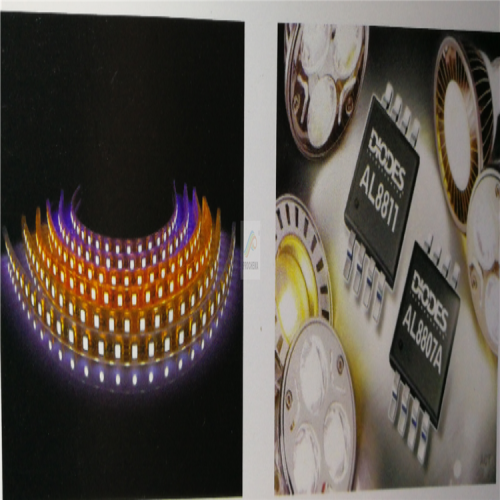

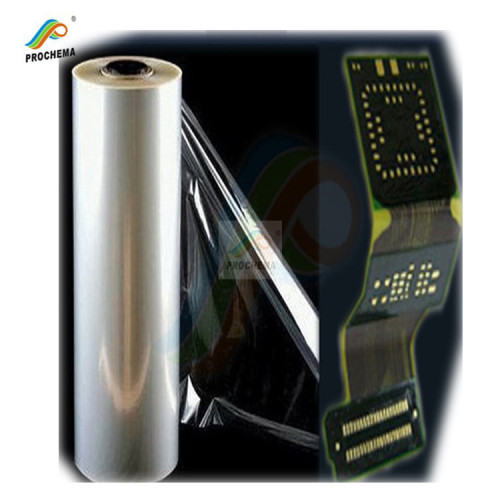

Fourth, electronic field (50-150um)

ETFE film can also be used to make special wire and cable insulation layer, ordinary fluorine plastics such as PTFE, PFA, FEP, in addition to the lack of mechanical strength, radiation resistance is also poor, and ETFE because of high mechanical strength, relatively small density, radiation resistance and other characteristics, has become an important material in the field of aerospace insulation wire and cable.

Q: What's your supportive policy for distributors in overseas market?

A:We support in many aspects including marketing, promotion, product developmentimprovements