>

<

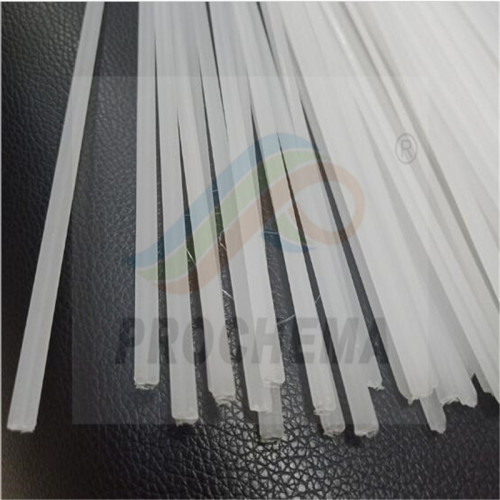

Dia3mm to Dia5mm ETFE anti-corrosion Plastic welding rod

Price:

$45.00 - $70.00/Kilogram

Mianyang Prochema Commercial Co.,Ltd.

22 YRS

Mianyang, Sichuan, China

Business type:Manufacturer,Trade Company,Distributor/Wholesaler

Close

Basic Info

Place of Origin

China

Productivity

1 ton/month

Supply Ability

1 ton/month

Payment Type

L/C,T/T,D/P,D/A,Paypal

Incoterm

FOB,Express Delivery,CFR,CIF,DAF,EXW,DES,FAS,FCA,CPT,CIP,DEQ,DDP,DDU

Certificate

ISO

Transportation

Ocean,Land,Air,Express

Port

shanghai,shenzhen,guangzhou

View All Details

Product Description

**ETFE Welding Rods: Characteristics and Applications**

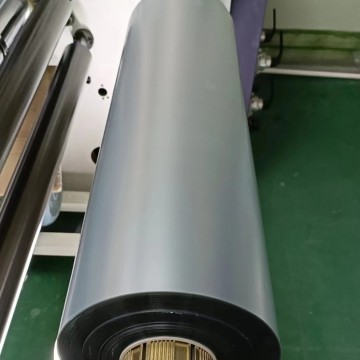

ETFE (Ethylene Tetrafluoroethylene) welding rods, also known as ETFE filler wires, play a critical role in the fabrication of ETFE membranes, which are widely used in architectural applications such as tensile structures, sports arenas, and exhibition halls due to their lightweight, high strength, and excellent weather resistance properties. These rods are specifically designed for welding ETFE films, enabling the creation of complex geometries and ensuring the structural integrity of ETFE installations.

### Key Characteristics of ETFE Welding Rods

1. **Material Composition**: ETFE welding rods are typically made from a blend of ethylene and tetrafluoroethylene, which provides them with unique chemical stability and low friction properties. This composition ensures that they can withstand the rigors of welding processes without degrading the ETFE membrane's integrity.

2. **Welding Efficiency**: These rods are engineered to facilitate efficient welding of ETFE membranes. They allow for smooth and consistent welding operations, which is crucial for achieving tight seals and maintaining the airtightness of ETFE structures.

3. **Adhesion**: ETFE welding rods are designed to have strong adhesion capabilities when fused with ETFE films. This ensures that the welded joints are strong and durable, capable of withstanding environmental stresses such as wind, rain, and temperature fluctuations.

4. **Durability and Weather Resistance**: The materials used in ETFE welding rods are chosen for their exceptional durability and weather resistance. This means that the welding process itself contributes to the long-term performance and aesthetic appeal of ETFE installations.

5. **Flexibility**: These rods are flexible enough to accommodate the curvature and shape complexities often found in ETFE membrane structures. This flexibility allows for precise welding in intricate designs without compromising the structural integrity or the visual quality of the final product.

### Applications

- **Architectural Membrane Structures**: ETFE welding rods are indispensable in the construction of tensile roof structures, where they enable the creation of large, open spaces with minimal material use and high energy efficiency.

- **Sports Arenas**: In the design of modern sports venues, ETFE membranes are favored for their transparency and light diffusion properties, providing natural lighting and a sense of openness while maintaining structural strength.

- **Exhibition Halls and Cultural Centers**: ETFE structures are used in these settings not only for their aesthetic qualities but also for their ability to adapt to various shapes and sizes, offering unique spatial experiences.

- **Environmental Sustainability**: Given the recyclable nature of ETFE and its ability to last for decades without significant maintenance, ETFE structures constructed using ETFE welding rods contribute to sustainable building practices.

In summary, ETFE welding rods are essential tools in the fabrication of ETFE membranes, offering a combination of technical precision and environmental sustainability that makes them a preferred choice in modern architectural design.

ETFE (Ethylene Tetrafluoroethylene) welding rods, also known as ETFE filler wires, play a critical role in the fabrication of ETFE membranes, which are widely used in architectural applications such as tensile structures, sports arenas, and exhibition halls due to their lightweight, high strength, and excellent weather resistance properties. These rods are specifically designed for welding ETFE films, enabling the creation of complex geometries and ensuring the structural integrity of ETFE installations.

### Key Characteristics of ETFE Welding Rods

1. **Material Composition**: ETFE welding rods are typically made from a blend of ethylene and tetrafluoroethylene, which provides them with unique chemical stability and low friction properties. This composition ensures that they can withstand the rigors of welding processes without degrading the ETFE membrane's integrity.

2. **Welding Efficiency**: These rods are engineered to facilitate efficient welding of ETFE membranes. They allow for smooth and consistent welding operations, which is crucial for achieving tight seals and maintaining the airtightness of ETFE structures.

3. **Adhesion**: ETFE welding rods are designed to have strong adhesion capabilities when fused with ETFE films. This ensures that the welded joints are strong and durable, capable of withstanding environmental stresses such as wind, rain, and temperature fluctuations.

4. **Durability and Weather Resistance**: The materials used in ETFE welding rods are chosen for their exceptional durability and weather resistance. This means that the welding process itself contributes to the long-term performance and aesthetic appeal of ETFE installations.

5. **Flexibility**: These rods are flexible enough to accommodate the curvature and shape complexities often found in ETFE membrane structures. This flexibility allows for precise welding in intricate designs without compromising the structural integrity or the visual quality of the final product.

### Applications

- **Architectural Membrane Structures**: ETFE welding rods are indispensable in the construction of tensile roof structures, where they enable the creation of large, open spaces with minimal material use and high energy efficiency.

- **Sports Arenas**: In the design of modern sports venues, ETFE membranes are favored for their transparency and light diffusion properties, providing natural lighting and a sense of openness while maintaining structural strength.

- **Exhibition Halls and Cultural Centers**: ETFE structures are used in these settings not only for their aesthetic qualities but also for their ability to adapt to various shapes and sizes, offering unique spatial experiences.

- **Environmental Sustainability**: Given the recyclable nature of ETFE and its ability to last for decades without significant maintenance, ETFE structures constructed using ETFE welding rods contribute to sustainable building practices.

In summary, ETFE welding rods are essential tools in the fabrication of ETFE membranes, offering a combination of technical precision and environmental sustainability that makes them a preferred choice in modern architectural design.

Q: What's your supportive policy for distributors in overseas market?

A:We support in many aspects including marketing, promotion, product developmentimprovements

You May Also LikeRelated Keywords

You May Also Like

>

<

Other popular products

>

<

Contact Now