Home - Products center > The application of ETFE (Ethylene Tetrafluoroethylene) membrane in the aviation field

>

<

The application of ETFE (Ethylene Tetrafluoroethylene) membrane in the aviation field

Price:

-

$6.00≥5000 Square Meter

Mianyang Prochema Commercial Co.,Ltd.

22 YRS

Mianyang, Sichuan, China

Business type:Manufacturer,Trade Company,Distributor/Wholesaler

Close

Basic Info

Place of Origin

China

Supply Ability

50000m2/Month

Payment Type

L/C,T/T,D/P,D/A,Paypal

Incoterm

FOB,Express Delivery,CFR,CIF,DAF,EXW,DES,FAS,FCA,CPT,CIP,DEQ,DDP,DDU

Certificate

ISO

Transportation

Ocean,Land,Air,Express

Port

shanghai,guangzhou,shenzhen

View All Details

Product Description

The application of ETFE (Ethylene Tetrafluoroethylene) membrane in the aviation field

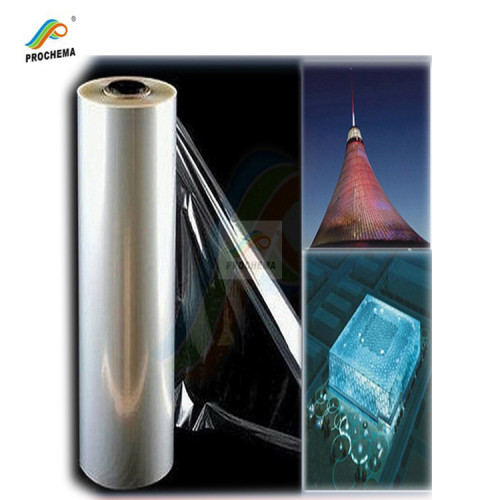

The application of ETFE (Ethylene Tetrafluoroethylene) membrane in the aviation field refers to the use of ETFE membrane materials in various aspects of aviation, such as aircraft structures, airport construction, and aerospace engineering. ETFE is known for its high strength, lightweight, durability, and excellent weather resistance, making it an ideal material for these applications.

In aircraft structures, ETFE can be used for the production of lightweight, high-strength components that can enhance fuel efficiency and performance. In airport construction, ETFE membranes are often utilized in the design of large-span, translucent roof systems, providing natural light while maintaining structural integrity and energy efficiency. In aerospace engineering, ETFE may also play a role in the development of lightweight, yet robust materials for spacecraft and satellites.

Please note that specific applications within the aviation field might vary depending on the context or specific industry needs.

In aircraft structures, ETFE can be used for the production of lightweight, high-strength components that can enhance fuel efficiency and performance. In airport construction, ETFE membranes are often utilized in the design of large-span, translucent roof systems, providing natural light while maintaining structural integrity and energy efficiency. In aerospace engineering, ETFE may also play a role in the development of lightweight, yet robust materials for spacecraft and satellites.

Please note that specific applications within the aviation field might vary depending on the context or specific industry needs.

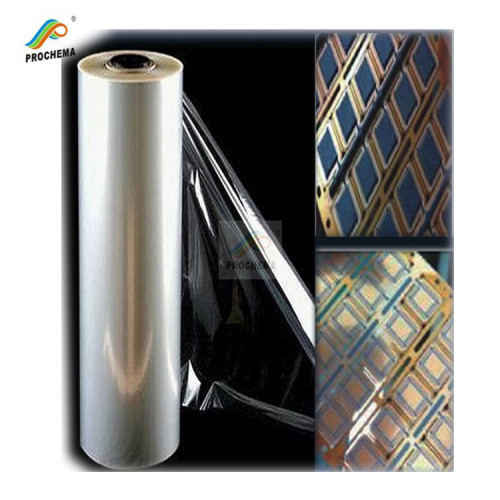

The application of ETFE membrane in aircraft interior decoration refers to the utilization of ETFE (Ethylene Tetrafluoroethylene) membrane materials in the design and manufacturing of aircraft interiors. ETFE is known for its lightweight, high transparency, and durability, making it an attractive choice for various applications within aircraft interiors.

ETFE can be used in several ways:

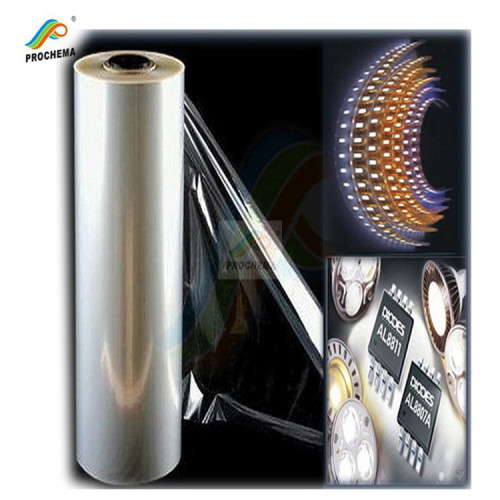

1. **Lighting Systems**: ETFE films can be used to create translucent surfaces that allow natural light to penetrate the cabin, enhancing the overall lighting experience while reducing the need for artificial lighting.

2. **Interior Panels and Skins**: The material can be integrated into the cabin walls, ceilings, or partitions, offering a sleek, modern aesthetic with enhanced acoustic properties.

3. **Skydome and Skybox Applications**: In private jets and luxury cabins, ETFE can be used to create transparent domes or boxes, providing passengers with panoramic views from above, such as a skylight or a viewing bubble.

4. **Baggage Compartment Linings**: ETFE can also be used in the lining of baggage compartments due to its resistance to abrasion and chemicals, ensuring durability and longevity.

5. **Custom Fabrics and Upholstery**: ETFE can be incorporated into custom fabrics or upholstery, offering a unique, futuristic look while maintaining high levels of comfort and resistance to wear and tear.

These applications not only enhance the aesthetic appeal of the aircraft interiors but also contribute to energy efficiency and passenger comfort.

ETFE can be used in several ways:

1. **Lighting Systems**: ETFE films can be used to create translucent surfaces that allow natural light to penetrate the cabin, enhancing the overall lighting experience while reducing the need for artificial lighting.

2. **Interior Panels and Skins**: The material can be integrated into the cabin walls, ceilings, or partitions, offering a sleek, modern aesthetic with enhanced acoustic properties.

3. **Skydome and Skybox Applications**: In private jets and luxury cabins, ETFE can be used to create transparent domes or boxes, providing passengers with panoramic views from above, such as a skylight or a viewing bubble.

4. **Baggage Compartment Linings**: ETFE can also be used in the lining of baggage compartments due to its resistance to abrasion and chemicals, ensuring durability and longevity.

5. **Custom Fabrics and Upholstery**: ETFE can be incorporated into custom fabrics or upholstery, offering a unique, futuristic look while maintaining high levels of comfort and resistance to wear and tear.

These applications not only enhance the aesthetic appeal of the aircraft interiors but also contribute to energy efficiency and passenger comfort.

Q: What's your supportive policy for distributors in overseas market?

A:We support in many aspects including marketing, promotion, product developmentimprovements

You May Also LikeRelated Keywords

You May Also Like

>

<

Other popular products

>

<

Contact Now