-

$219.00≥5 Square Meter

Business type:Manufacturer,Trade Company,Distributor/Wholesaler

Fuel Cell Proton Exchange Membrane N30 N41

Perfluorinated proton membrane is a single component perfluorinated sulfonic acid H-type perfluorinated ionic membrane product produced by strip spreading process. As a solid electrolyte separating anode and cathode in various electrolytic cells and batteries, membrane has the property of one-way passage of cations. Due to the use of polytetrafluoroethylene as the main chain, the most appropriate molecular weight and ion exchange capacity, membrane has the characteristics of chemical resistance and durability. Widely used in: vanadium battery, liquid flow battery, fuel cell, electrolytic water hydrogen production and other fields.

Our PFSA membranes perform as a solid polymer electrolyte in fuel cells and other applications in electrochemistry and separation technology for a variety of electrochemical process and devices including chlor-alkali cells.The membranes are located between the cathode and anode and transports protons formed near the catalyst at the hydrogen electrode to the oxygen electrode thereby allowing the current to be drawn from the cell.

PFSA N-3010 N-3015 and N-3025 membranes are reinforced membranes based on chemically stable perfluorosulfonic acid (PFSA) copolymer. Incorporation of the porous reinforcement such as ePTFE improves the mechanical property of the composite membrane and allows the membrane to restrict its swelling. The membranes show significant improvements in features such as better resistance to chemical attack and longer operating durability in fuel cells.

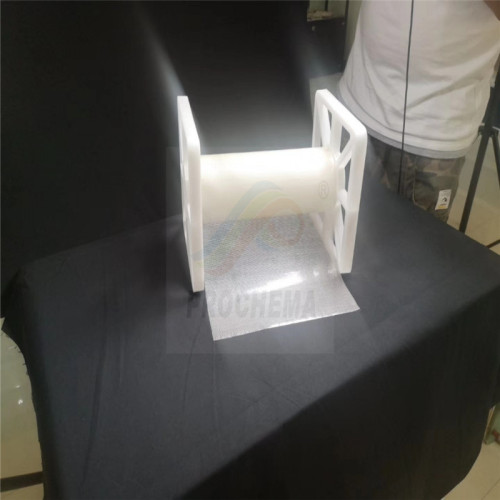

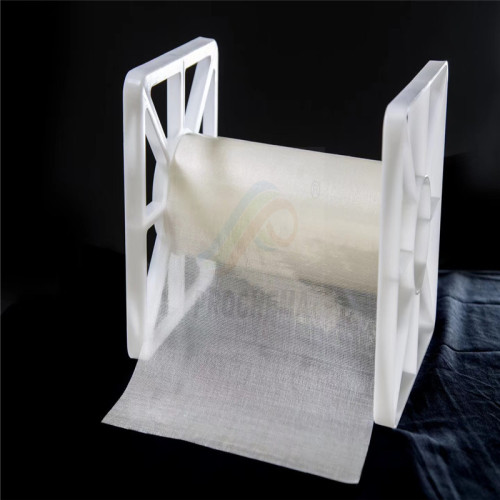

The membrane is typically positioned on a coversheet. This composite membrane is wound on a plastic core, with the coversheet on the core-side, as shown in Figure 1. A 15.24cm ID plastic roll core is standard.

The membrane combined with the coversheet eliminates rapid changes in the membrane’s water content, and stabilizes the dimensions of the membrane when removed from the roll.

Order and Packaging Information

Our PFSA membranes are available in two thickness values: N-3010 N-3015 and N-3025.

The standard product specifications for membrane pieces include:

l Width: 0.30 m (min.) to 1.00 m (max.)

l Length: 0.30 m (min.) to 1.00 m (max.)

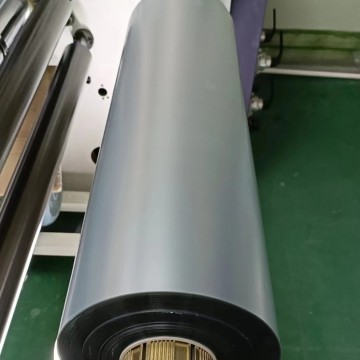

The membrane for cut pieces will depend on the size and quantity of the customer’s order requirements. All the flatted membranes are shipped on a roll. Flat membranes are directly wound into a small roll. The membranes are protected with a polyethylene wrap and inner packaging, then placed in shipping hard cartons.

The standard product specifications for membrane rolls include:

l Width: 610mm and 800mm standard widths; other widths are available from 200mm to 400mm in 100mm increments on special order.

l Length: 100-meter standard roll length, other non-standard lengths are feasible to meet orders of the custome.

There is a 50 m2 minimum order requirement for non standard roll widths and lengths. Membrane pieces or rolls can be cut to non standard sizes, and special packaging provided at additional cost. Please contact our sales staff for details and availability.

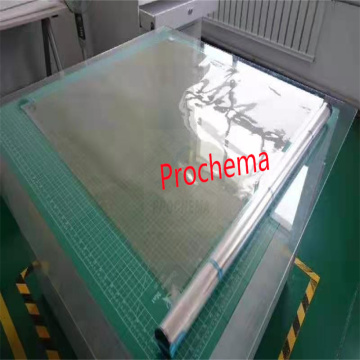

Membrane dimensions are based on dry product conditioned at 23 °C and 50% relative humidity(RH) before cutting. The moisture content of the membranes will have an influence on their size changes including in the length, width, and thickness directions. Once the coversheet is removed, the membrane will adjust to the environment conditions. The membrane typically adheres to the coversheet, to the extent that it reduces the dimensions.

Table 1. Properties of PFSA membrane:

Thickness and Basis Weight Properties

Membrane Type

Thickness(microns)

Weight(g/m2)

N-3010

10

20

N-3015

15

30

Physical and Other Properties

Values

Physical Properties meastured at 50% RH, 23 °C

N-3015

MD TD

N-3025

MD TD

Test Method

Tensile Strength, max., MPa

22

29

25

32

GB/T 20042.3-2009

Tensile Modulus, MPa

250

280

300

325

GB/T 20042.3-2009

Elongation at Break, %

150

180

220

230

GB/T 20042.3-2009

Other Properties

Values

Properties

N-3015

N-3025

Test Method

Conductivity(at 100% RH, 23 °C), S/cm

0.085

0.085

GB/T 20042.3-2009

Hydrogen Crossover, (ml/min·cm2)

<0.010

<0.010

GB/T 20042.3-2009

Hydrolytic Properties

Values

Hydrolytic Properties

N-3015

N-3025

Test Method

Water Content, % water (50% RH, 23 °C)

8.0± 3.0%

8.0± 3.0%

GB/T 20042.3-2009

Water Uptake, % water (50% RH, 100 °C,1h)

15.0± 5.0%

15.0± 5.0%

GB/T 20042.3-2009

Linear expansion, % increase

from 50% RH, 23 °C to water soaked, 23 °C

from 50% RH, 23 °C to water soaked, 100 °C

2%(MD),5%(TD)

3%(MD),10%(TD)

2%(MD),10%(TD)

3%(MD),13%(TD)

GB/T 20042.3-2009

GB/T 20042.3-2009

N 41X is hybrided by high strength PTFE fabric and Perfluorinated ion exchange Resin. Thus our film has many outstanding features. It not only has the high tensile strength ,high selection,isotropy,high conductance;but also has the effect of self-humidifying and with low Linear Expansion. It has the good performance in Fuel Cell ,Vanadium batteries,electrolyzer,

electrodialysis,elect-chemical sensors as the solid electrolyte film .

Thickness and Weight :

Type

Thickness (um)

N -417

250

N -4110

350

X can be 5-20mil , Special thickness and size ,please contact1mil=25.4um

Size:Length x width : 600x600 800x800mm

N series Performance :

Performance

Numerical

Method

Tensile strength

40MPa (23oC,50% RH,Isotropy)

ASTMD885

Tensile Modulus

780MPa(23oC,50% RH,Isotropy)

ASTMD882

Linear Expansion

1%( 23oC,from50%RH,to water soaked)

ASTM756

Water Uptake

50±5% (100oC,1h)

ASTMD570

Conductivity

0.1S/cm

25oC,zawodzinski

Equivalent weight

950g/eq

Test method designed by Factory

Main usage :

Used for electrolysis field : higher intensity of biological fuel cells , watertreatment, chlor-alkali producing etc.

Q: What's your supportive policy for distributors in overseas market?

A:We support in many aspects including marketing, promotion, product developmentimprovements