Home - Products center > Electrolysis Of Water For Hydrogen Production Using Proton Exchange Membrane (PEM)

>

<

Electrolysis Of Water For Hydrogen Production Using Proton Exchange Membrane (PEM)

Price:

-

$990.00≥5 Square Meter

Mianyang Prochema Commercial Co.,Ltd.

22 YRS

Mianyang, Sichuan, China

Business type:Manufacturer,Trade Company,Distributor/Wholesaler

Close

Basic Info

Place of Origin

China

Productivity

1000000m2/year

Supply Ability

10000m2 per month

Payment Type

L/C,T/T,D/P,D/A,Paypal,Others

Incoterm

FOB,DDU,Express Delivery,CFR,CIF,EXW,DAF,FAS,DES,FCA,CPT,CIP,DEQ,DDP

Certificate

ISO

HS Code

3921909001

Transportation

Ocean,Land,Air,Express,Others

Port

shanghai,guangzhou ,shenzhen

View All Details

Product Description

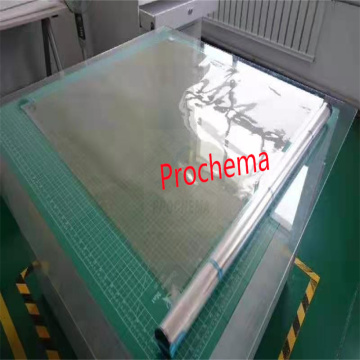

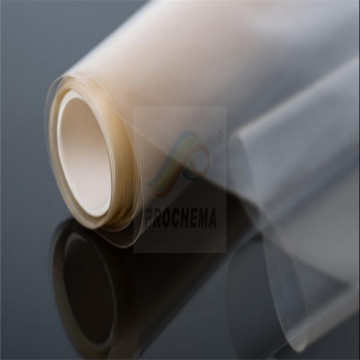

Electrolysis of water for hydrogen production using proton exchange membrane (PEM) N117 N116W N41

Introduction:

The electrolysis of water is a promising method for producing hydrogen gas, which can be used as a clean and renewable energy source. In this process, a proton exchange membrane (PEM) plays a crucial role in separating the hydrogen and oxygen gas produced during electrolysis. This membrane allows the selective transport of protons, while blocking the passage of other species, such as electrons and gas molecules.Composition and Structure:

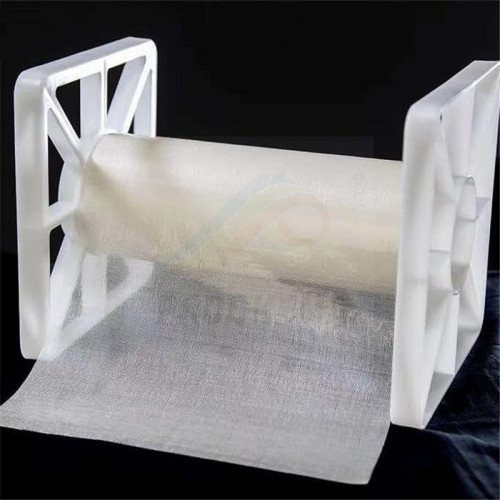

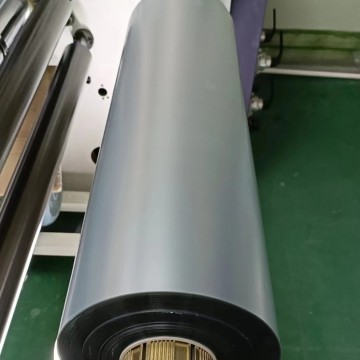

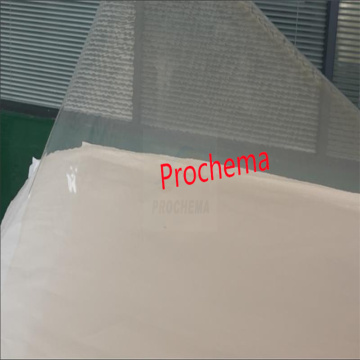

The PEM used for water electrolysis is typically composed of a solid polymer electrolyte, which is a thin, flexible, and proton-conductive material. The most commonly used material for PEM is a perfluorosulfonic acid (PFSA) polymer, such as Nafion. This polymer consists of a fluorinated carbon backbone with pendant sulfonic acid groups, which provide the necessary proton conductivity.

Working Principle:

During water electrolysis, an electric current is passed through the PEM, causing the water molecules to split into hydrogen and oxygen ions. The protons (H+) are transported through the PEM, while the electrons (e-) flow through an external circuit. The protons combine with electrons on the other side of the membrane to form hydrogen gas, while the oxygen ions react to form oxygen gas. The PEM ensures that only protons can pass through, preventing any mixing of gases.

Advantages:

1. High proton conductivity: The PEM exhibits excellent proton conductivity, allowing for efficient separation of hydrogen and oxygen gases.

2. Low gas crossover: The PEM effectively blocks the passage of gases, preventing any mixing or contamination of the produced gases.

3. Durability: The PEM is chemically stable and can withstand the harsh conditions of water electrolysis, ensuring a long lifespan.

4. Flexibility: The thin and flexible nature of the PEM allows for easy integration into various electrolysis systems.

Applications:

The PEM is widely used in various water electrolysis systems, including polymer electrolyte membrane (PEM) electrolyzers and proton exchange membrane fuel cells (PEMFCs). These technologies have applications in hydrogen production, energy storage, and transportation sectors.

Conclusion:

The proton exchange membrane is a critical component in the electrolysis of water for hydrogen production. Its selective proton transport properties ensure efficient separation of hydrogen and oxygen gases. With its excellent conductivity, durability, and flexibility, the PEM plays a vital role in advancing the development of clean and sustainable energy solutions.

Q: What's your supportive policy for distributors in overseas market?

A:We support in many aspects including marketing, promotion, product developmentimprovements

You May Also LikeRelated Keywords

You May Also Like

>

<

Other popular products

>

<

Contact Now