-

$3.00≥200 Meter

Business type:Manufacturer,Trade Company,Distributor/Wholesaler

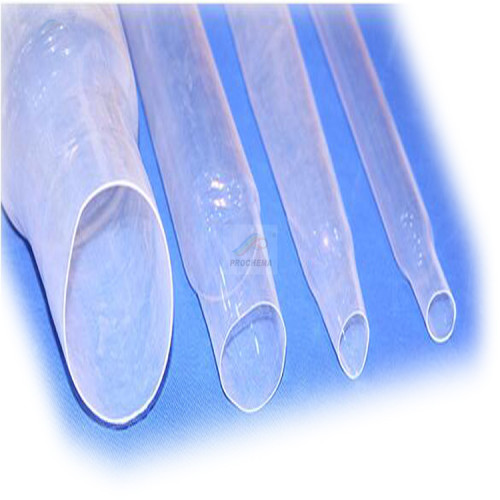

FEP UV lamp cover , FEP heat shrink tube for UV lamp protection

Specification : From T3 to T12 thickness : postshrink thickness 0.2-0.3mm

Size can be customised

Shape can be used for single round lamp, H shape lamp, U shape lamp

Introduction:

FEP is both transparent to UVA and UVC light and totally resistant to it as well as being temperature resistant. Therefore it makes an excellent, safe material for shatterproofing UV lamps used in the food and pharmaceutical industries, as well as standard fluorescent lamps, where glass free areas are required.

· Our fep heat shrink tube meets the health and safety audits within the pharmaceutical, food processing and agricultural industries.

· it has a maximum continuous operating temperature of 200° C and does not enbrittle or discolour over time as with other coatings. The integrity of the coating will long outlast the life of the lamp.

FEP Shatterproof lamp coatings are used in the following fields:

· Schools and Colleges

· Public spaces

· Hotels and Restaurants

· Warehousing and storage

· Food processing plants

· Food preparation and display areas

· Supermarkets

· Bakeries

· Pharmaceutical plants

· Medical centres, Dentists and hospitals

· Leisure centres and swimming pools

· Agricultural Industry

· Stables and Liveries

Protect your own lamps

Our FEP heat shrink sleeving was designed specifically for use with insect and germicidal lamps. Due to the unique properties of FEP this coating will not discolour and become brittle due to the absorption of UV radiation, which is a common problem with lesser quality coatings. The UV transmission rate remains high at approx. 95% for UVA and approx. 85% for UVC, thereby ensuring you have maximum performance for the lifetime of the lamp.

FEP heat shrinkable sleeves and boots have been developed specifically to enable distributors, stockists, and large users of lamps to be able to make lamps shatterproof very easily in their own premises in small or large quantities. The bespoke process equipment is minimal, and coating can be applied with virtually no training to unskilled personnel.

This coating can be applied to all configurations of lamps.

The FEP coating will outlast the life of the lamp, where other inferior plastic coverings enbrittle or discolour under the effect of the UV radiation. If the lamp suffers damage the glass, etc. is contained in the shrunk on jacket.Data sheet:

|

Indicator

|

Unit

|

Indicator figure

|

|

|

|

density

|

g/cm3

|

2.14-2.17

|

|

|

|

Tensile strength

|

Mpa

|

14 |

|

|

|

Ultimate elongation

|

%

|

175

|

|

|

|

Temperature range

|

°C

|

- 200-200

|

|

|

|

Dielectricity strength

|

Kv/mm

|

15

|

|

|

Q: What's your supportive policy for distributors in overseas market?

A:We support in many aspects including marketing, promotion, product developmentimprovements