-

$5000.00≥2 Set/Sets

Business type:Manufacturer,Trade Company,Distributor/Wholesaler

FEP anticorrosive heat exchanging tube and exchanger

FEP has comprehensive advantages that other materials can not compete with, especially its temperature characteristics and corrosion resistance in heat exchangers, which makes FEP heat exchangers widely used in corrosion-resistant industries, such as chemical industry, pickling, electroplating, medicine, anodic oxidation and so on.

FEP heat exchanger has excellent corrosion resistance and aging resistance. Because of its excellent temperature resistance, it is suitable for both steam heating and hot water heating.

FEP heat exchanger is a new type of corrosion-resistant heat exchanger developed in recent ten years. The main results are shell and tube type and immersion type. It has unparalleled chemical and thermal stability (- 200 - 200 C). The tubesheet and bundle of F46 heat exchanger (3-10mm capillary) are sintered by advanced powder metallurgy process, with excellent performances. Through unique and advanced welding method, the connection strength between tube bundle and tube sheet of fep heat exchanger reaches 1.5 Mpa.

Fep heat exchanger has excellent corrosion resistance. Because fep is an inert chemical material, it can work in almost all media except elemental fluorine at high temperature, molten alkali metal, chlorine trifluoride, uranium hexafluoride and perfluorinated kerosene. For example: concentrated hydrochloric acid, hydrofluoric acid, sulfuric acid, nitric acid, phosphoric acid, acetic acid, oxalic acid, caustic sodium, sodium hypochlorite, naphthalene, benzene, xylene, acetone, Aqua regia, chlorine, toluene, various organic solvents, etc.

FEP heat exchanger has good scale resistance. Due to the chemical inertia, smooth surface, winding and high expansion coefficient of fep tubes, it is difficult to scale the heat transfer surface, which greatly reduces the number of equipment maintenance and ensures relatively stable heat transfer coefficient and long-term operation of production.

FEP heat exchanger has good heat transfer performance. Because the heat exchanger is a thin-walled tube with a wall thickness of only 0.5 mm, 0.75 mm and 1 mm, the shortcoming of low thermal conductivity of FEP material is overcome, and its total heat transfer coefficient can reach 150-300 (W/m2.K).

The resistance of fep heat exchanger is small. Because of its small friction coefficient, low roughness and excellent lubrication performance, the resistance of the fluid in the tube bundle is smaller than that in the metal tube bundle; the fep heat exchanger is small in volume, light in weight and compact in structure.

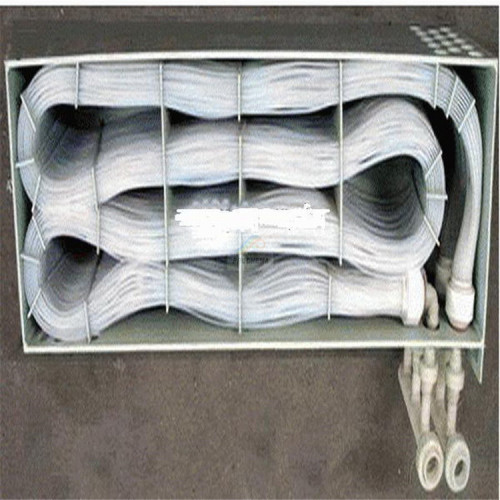

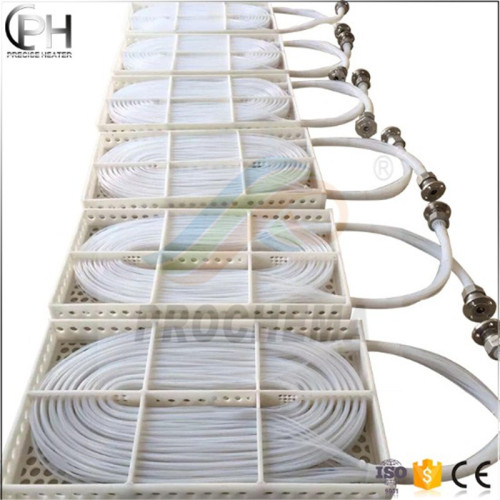

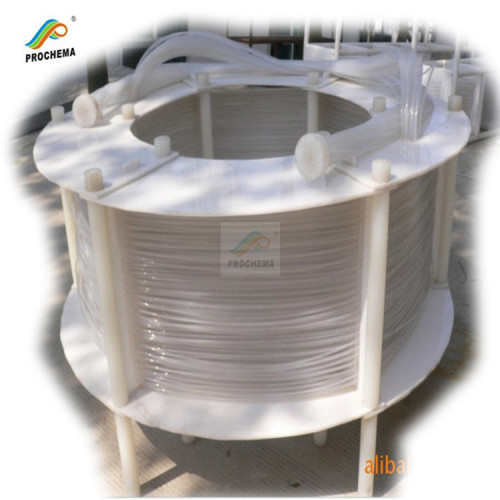

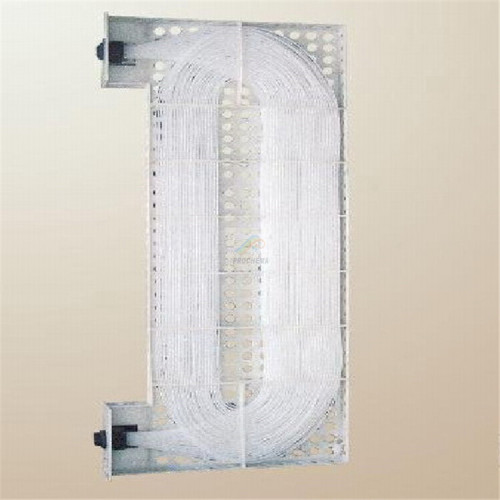

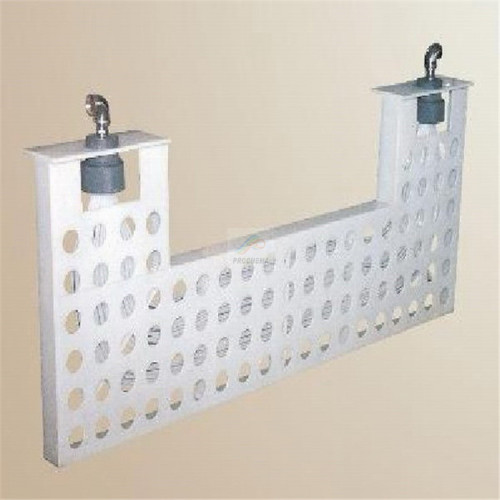

Specification:There are many types of heat exchangers, including W type, L type, U type, O type, plate type and surround type immersive heat exchangers, tower type and shell type heat exchangers

Standard coils are FEP and rated up to 30 PSI steam service. PFA coils are available for steam service up to 60 PSI. 5.5 square foot to 120 square foot of exchange area standard.

Tubing sizes: 1/2 inch (13mm) diameter for larger coils and 1/4 inch (7mm) diameter for smaller coils. size can be customised

OPTIONS AVAILABLE

Custom configuration including bottom style exchangers.

Anti-floatation brackets.

Special manifold configurations.

Dual coils for both heating and cooling.

NOTE: Vacuum breakers recommended for fluoropolymer heat exchanger steam heating installations.

Grooves of acid, plating bath hromeplate bath, etc

Heating or cooling by water is a routine application, but if you use stream or other high temperature/ high pressure method to heating, please tell us before you place the order.

For heating or cooling of most aqueous acid and alkaline solutions.

All wetted parts of fluoropolymer (FEP, PFA or PTFE) construction.

Heavy duty CPVC mounting bracket.

2 to 4 inch thick perforated guard helps protect the coil from damage.

Heavy wall tubing improves circulation and minimizes pressure drop.All coils constructed of ½-inch (13mm) tubing

Integral Flexible inlet and outlet manifolds for single point connections greatly reduce the potential for leaks and simplify installation.

Standard coils are made from FEP (Fluorinated Ethylene Propylene) and rated up to 30 PSI steam service.

PFA (Perfluoroakoxy resin) coils are available for steam service up to 60 PSI.

10 PSI minimum steam pressure required for operation.

Consult factory regarding pressure reduced applications.

Eliminates stray currents in the tank.

5.5 ft2 to 120 ft2 of exchange area standard.

NOTE: Vacuum breakers recommended for fluoropolymer heat exchanger steam heating installations. Please consult factory regarding pressure reduced steam applications.

PFA is a copolymer of tetrafluoroethylene and perfluoroalkyl vinylether. It is a perfluoro polymer consisting of only carbon atoms and fluorine atoms without any hydrogen atom.

FEP (FEP) and graphite heat exchanger is to replace carbon steel heat exchanger heat exchanger and successful development, the design structure, give full play to the advantages of FEP materials, widely used in acid, alkali, salt, oxidant, organic solvents, such as liquid - liquid, gas - liquid exchange occasion, especially suitable for salt industry hydrofluoric acid cooling cooling and sulfuric acid, phosphate fertilizer production in electroplating, electrolysis, degreasing, pickling, electroless plating nickel phosphorus, anodic oxidation, aluminum piece, chemical, pharmaceutical, food and other corrosive liquid heating, condensation and evaporation, concentration, etc.

This product has less investment, convenient maintenance and cleaning, and obvious effect of energy saving and consumption reduction in use.

Product performance characteristics

|

Properties |

Description |

|

corrosion resistance |

It is not affected by any strong acid, alkali, oxidant and almost all solvent except fluorine under high temperature and pressure and molten alkali metal |

|

Stable heat transfer effect |

Excellent non-viscosity, heat exchange elements are not easy to scale, the thermal conductivity of long-term use of the product is basically stable; Tube wall slip, fluid pressure drop is small, tube bundle is flexible, easy to be affected by fluid impact to produce vibration, enhance turbulence, is conducive to heat transfer |

|

Leak less |

Basically can eliminate running, risk, drop, leak, do not need to stop production maintenance |

|

light in weight and occupies little space |

It covers an area of 1/6 iron pipes for heat exchange and weighs less than 1/10 |

|

long service life

|

Choose reasonable product structure, use properly, life in more than four years |

Specifications Series

Product series: straight tube and shell, U-shaped tube and shell, tube bundle:

|

|

No. |

Length(m) |

Nominal heat transfer area(m2) |

|

Straight through shell type |

FSZH |

1∽6 |

1∽60 |

|

U-shell type |

FSUGH |

1∽6 |

2∽100 |

|

Bundle type |

FSGH |

6∽16 |

2∽100 |

Q: What's your supportive policy for distributors in overseas market?

A:We support in many aspects including marketing, promotion, product developmentimprovements