-

$130.00≥100 Kilogram

Business type:Manufacturer,Trade Company,Distributor/Wholesaler

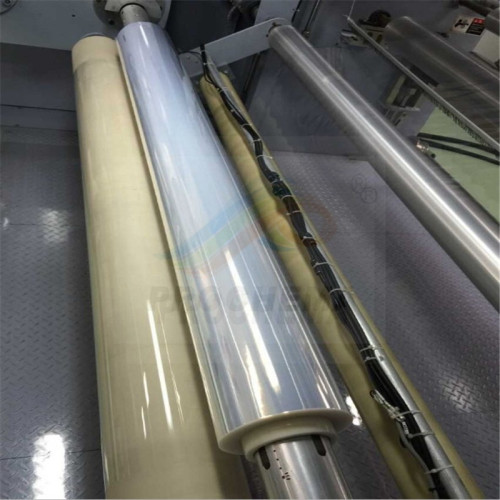

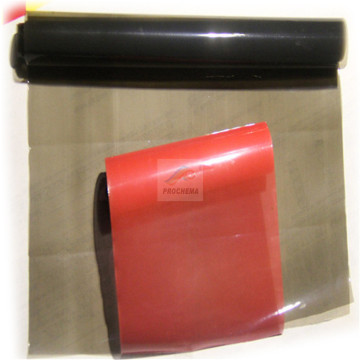

FEP 3D Printing Release Film 0.1 0.15 0.2mm

NFEP 3D Printing Release Film For DLP LCD SLA Resin 3D Printer

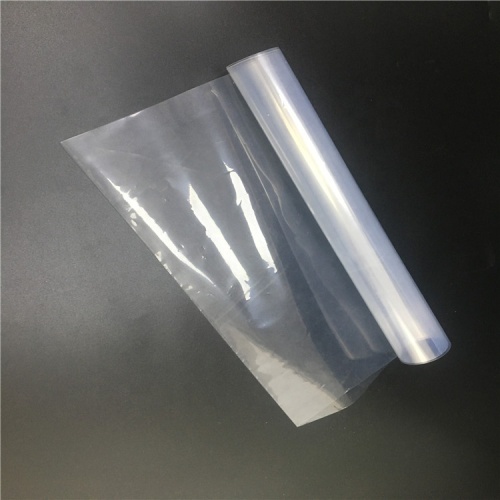

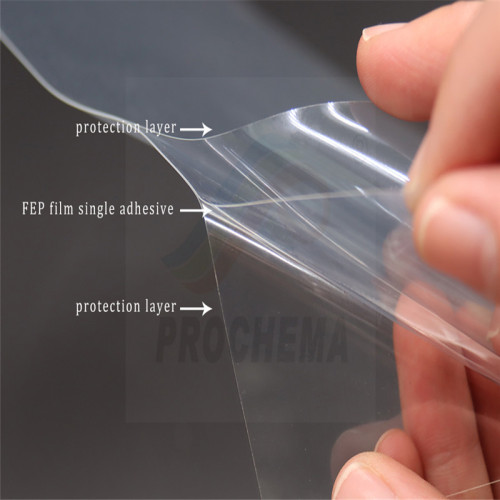

FEP fluoroplastic film has perfect properties of non-stick, temperature resistance,dielectric,mechanical,abrasive resistance etc. It is suitable for 3D printing(UV curable) releasing . FEP film has perfect releasing force,it can meets kinds of proucts' releasing requirements .High transmission of light let UV light can penetrate fully ,making the printed products more beautiful and improve products quality .

FEP releasing film properties :

Release force--good peeling performance,can be reused

High transmission of light-- above 95%

Anticorrosion--not effected by any Strong acids, bases, oxidizers and almost all solvents.

non-stick--smooth surface making better release property and durability

temperature resistance--working temperature -190oC to 240oC

Fireproof--UL94 V0 grade

Application :

special for DLP SLA 3D Printer UV curable releasing

Specification :

| Thickness | width | length | remar |

| 150um | 1250mm | 100-500m | thickness ,width,length can be customised |

| 180um | 1250mm |

100-500m |

| Item | Thickness(mm) |

Thickness Tolerance |

Width(mm) |

| FEP film | 0.05 | 0~+0.01 | 10-300 |

| 0.07 | |||

| 0.08 | |||

| 0.09 | |||

| 0.10 | |||

| 0.15 |

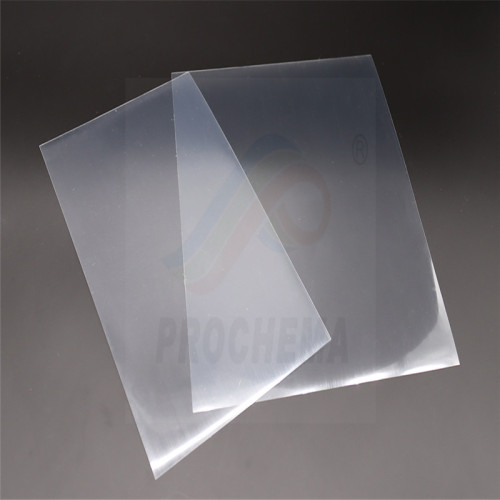

3D printer membrane sheet form

Q: What's your supportive policy for distributors in overseas market?

A:We support in many aspects including marketing, promotion, product developmentimprovements