Business type:Manufacturer,Trade Company,Distributor/Wholesaler

High conductivity, high output power.

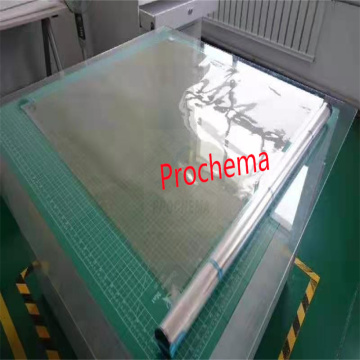

PEM, Proton Exchange Membrane or Polymer Electrolyte Membrane, also known as polymer electrolyte membrane. As can be seen from the name, its major function is to transfer protons, in addition, it is also necessary to isolate the fuel and oxidizer to prevent direct chemical reactions caused by penetration.

Proton Exchange Membrane Fuel (PEM) is a part of PEMFC. Inside the fuel cell, the PEM provides a channel for proton migration and transport, making protons pass through the membrane from anode to cathode, forming a loop with the electron transfer of the external circuit, and providing current to the outside world. PEM differs from the diaphragms used in general chemical power supplies. The material used as PEM has the characteristics of good proton conductivity, small electroosmotic effect of water molecules in the membrane, as small as possible permeability of gas in the membrane, good electrochemical stability, good dry and wet conversion performance, certain mechanical strength, good processability, and appropriate price. According to the structure of the membrane, the proton exchange membrane can be divided into three categories: inorganic acid doped membrane, composite membrane and sulfonated polymer membrane. Among them, the sulfonated polymer membrane includes three kinds of perfluorosulfonic acid proton exchange membrane (currently used as), partially fluorinated proton exchange membrane and non-fluorinated proton exchange membrane. Perfluorosulfonic acid proton exchange membrane is commonly used in the United States DuPont company's Nafion series membrane. The gas diffusion layer is an important part of the proton exchange membrane, which plays the role of supporting the catalyst layer, and is also the channel of the reaction gas and the product water, which has the role of supporting the catalyst layer, transporting gas and water, conducting electrons, heat transmission and distribution, chemical corrosion resistance and electrochemical corrosion resistance.

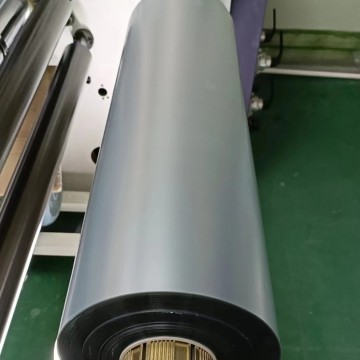

ePTFE (Expanded polytetrafluoroethylene) enhanced composite membrane technology expertise, ultra-thin, durable, high power density characteristics, high power output with very little energy loss, widely used in the world's leading fuel cell models,

Q: What's your supportive policy for distributors in overseas market?

A:We support in many aspects including marketing, promotion, product developmentimprovements