-

$200.00≥100 Kilogram

Business type:Manufacturer,Trade Company,Distributor/Wholesaler

PCTFE Chemical And Weather Resistance Dielectric Rod

PCTFE material = POLYfluoroethylene chloride referred to as PCTFE, by the polymerization of polyfluoroethylene chloride from the polymer compounds. Low molecular weight is liquid or waxy. The higher molecular weight is a white solid or dispersion. Solid density 2.1~2.2. The melting point of 208 ~ 210 ℃. Resistant to heat, acid, alkali and organic solvents (except halides), but not to molten caustic soda and elemental fluorine. Soluble in aromatic hydrocarbon and carbon tetrachloride. Chemical resistance is second only to ptfe. Can be used as engineering plastics. Tensile strength 3.096~4.135 mpa (316~422 kg force/cm 2). Generally used in chemical equipment with high performance requirements, insulated cables, radio, capacitance products and heat or low temperature resistant accessories. Dispersants are used to make anticorrosive coatings and films.

1. Contact with highly corrosive media, sealing and liner materials of high pressure system, transparent materials of observation window, etc

4. It can be widely used as corroding structural material, anti-corrosion lining of equipment, transparent viewing mirror, vacuum sealing material, electronic and electrical components, motor instrument parts, electrical insulation material, etc.

Applicable industry: PCTFE is widely used in low temperature and high pressure sealing parts (liquid nitrogen, liquid oxygen, etc.), semiconductor, chemical, pharmaceutical, aerospace and other related sealing fields.

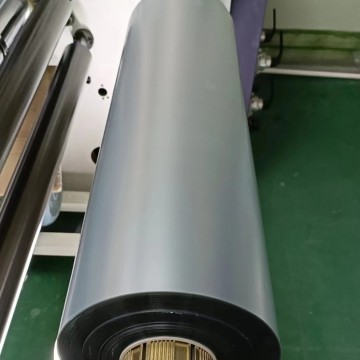

Polytrifluorochloroethylene (PCTFE) Material

Application Industry (examples of some industries)

Size:

|

Product |

thickness (mm) |

width (mm) |

length(mm) |

|

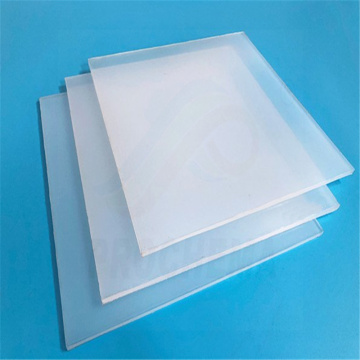

moulded sheet |

1-40 |

100-300 |

100-300 |

|

Product |

Dia (mm) |

Length (mm) |

|

moulded rod |

ф5-ф25 |

200 |

|

ф30-ф150 |

50-150 |

Extrucsion Rod: Dia10-150mm x L 2000mm

Technical data:

| Properties | units | Indicators |

| Density | g/cm3 | 2.1-2.2 |

| Tensile strength | MPa | ≥35 |

| Elongation at break | % | 20-100 |

| volume resistivity | Ω·cm | ≥1×1010 |

| Hardness | Shores hardness | D90 |

| breakdown voltage | Kv/mm | ≥15 |

| Temperature range | °C | -200°C~+120°C |

1.Dimensionally stable, rigid, and resistant to cold flow

2. Very low gas permeation and outgassing

3.Near zero moisture absorption

4. Excellent chemical resistance

5.Useful temperature range: –400°F to 380°F

6. Radiation resistance

Q: What's your supportive policy for distributors in overseas market?

A:We support in many aspects including marketing, promotion, product developmentimprovements