-

$3.00≥100 Piece/Pieces

Business type:Manufacturer,Trade Company,Distributor/Wholesaler

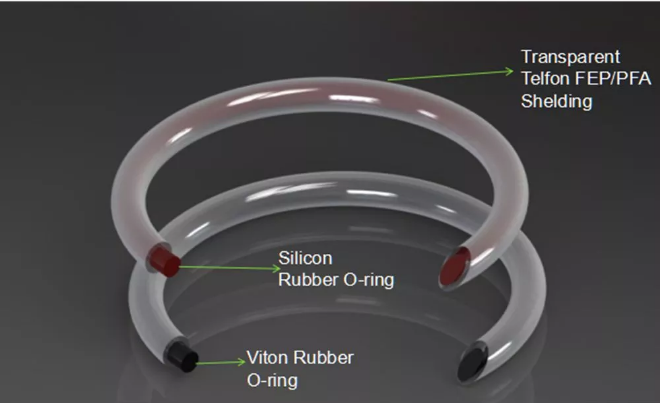

PTFE FEP PFA Encapsulated Solid Silicone Cord O Ring

Encap o-ring coated with plastic chemical resistance and rubber elasticity, the outer plastic wrap the inner rubber ring, mainly for pumps,valves, pipe flanges, boilers, heat exchangers, gas compressors, mechanical seals, Filters, reaction

vessels, pressure vessels, extraction equipment and more.

Outer plastic: Inner rubber:

1.FEP (-20 ~ 200 ℃) 1.Silicone

2.PFA (-20 ~ 260 ℃) 2.FKM / FPM

1. Duro: 30-90 Shore A

2. Size: Standard,Customized or Samples OEM

3. Certification: ISO/TS16949, SGS, FDA, ROHS

O-Ring with a FEP or PFA (PTFE) outer layer encapsulating a Silicone core. The PTFE shell offers excellent chemical and temperature resistance while the Silicone core provides the resiliency needed to provide effective sealing. Readily available in common USA and metric cross-sections and nearly unlimited diameters. FEP encapsulated Solid Silicone with improved chemical resistance up to 205℃. PFA encapsulated Solid Silicone up to 260℃.

Shore A Hardness:

Silicone:70°A

FKM: 70A

Hollow Silicone: 75-80°A

PTFE coated encapsulated O-rings are designed to combine the sealing properties of the rubber O-ring with the chemical resistance of PTFE. They are generally manufactured from FKM or silicone rubber and are coated in a thin molded layer of PTFE FEP or PFA. This provides a unique seal popular for high friction and aggressive chemical applications. FEP encapsulated O-rings are our most common and are resistant to solvents and chemicals (except for alkaline metals, fluorine and some halogenated compounds at high temperatures). They have a low coefficient of friction and a very low permeability to gases making them suitable for harsh environments. PTFE coated encapsulated o-rings also have a good elastomeric memory.We can also supply rigid PTFE o-rings which have a high compression set.

· Cost efficient alternative to Kalrez and similar perfluoroelastomer 'O'-Rings

· Low coefficient of friction allowing reduced wear of equipment

· Adaptive sealing force of an elastomeric 'O'-Ring

· Resistant to compression set/cold flow issues of solid 'O'-Rings

Encapsulation Options

· FEP Encapsulation

Standard material for all applications up to 205°C, resistant to virtually all chemicals and joined by an advanced heat moulding process to give a seamless encapsulation.

· PFA Encapsulation

Same properties as FEP encapsulation but with greater heat resistance for applications above 205°C. Also resistant to virtually all chemicals and joined seamlessly via advanced heat moulding process.

Silicone Inner Core Encapsulated o ring

Commercially best material option combined with lower Shore Hardness and greater elasticity than fkm, providing an excellent material choice for the majority of applications.

fkm Inner Core Encapsulated o ring

Greater chemical resistance than Silicone. If encapsulation is damaged, fkm provides greater resilience to chemical attack.

O-ring,gasket,washer,valve,bellow,strip,cord,cover,stopper,plug,piston and lots of other rubber

products can be provided.

Q: What's your supportive policy for distributors in overseas market?

A:We support in many aspects including marketing, promotion, product developmentimprovements