-

$150.00≥100 Kilogram

Business type:Manufacturer,Trade Company,Distributor/Wholesaler

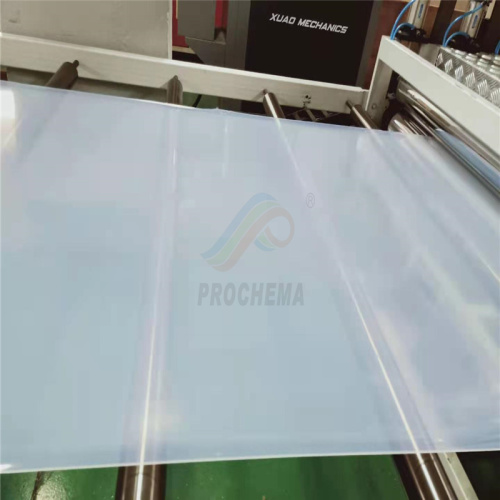

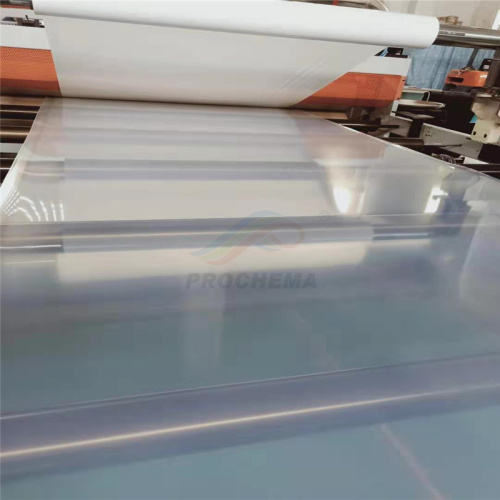

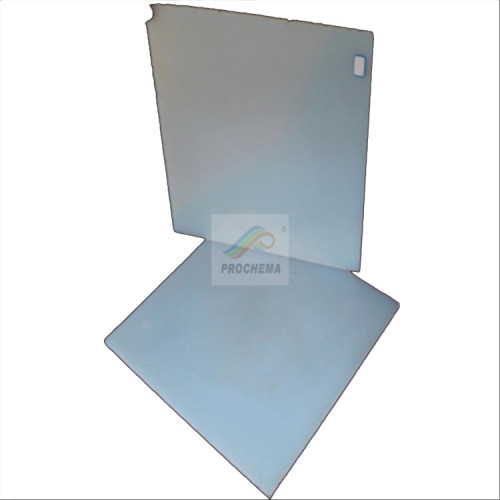

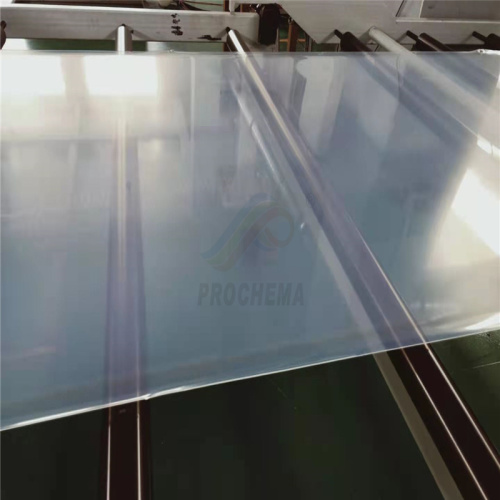

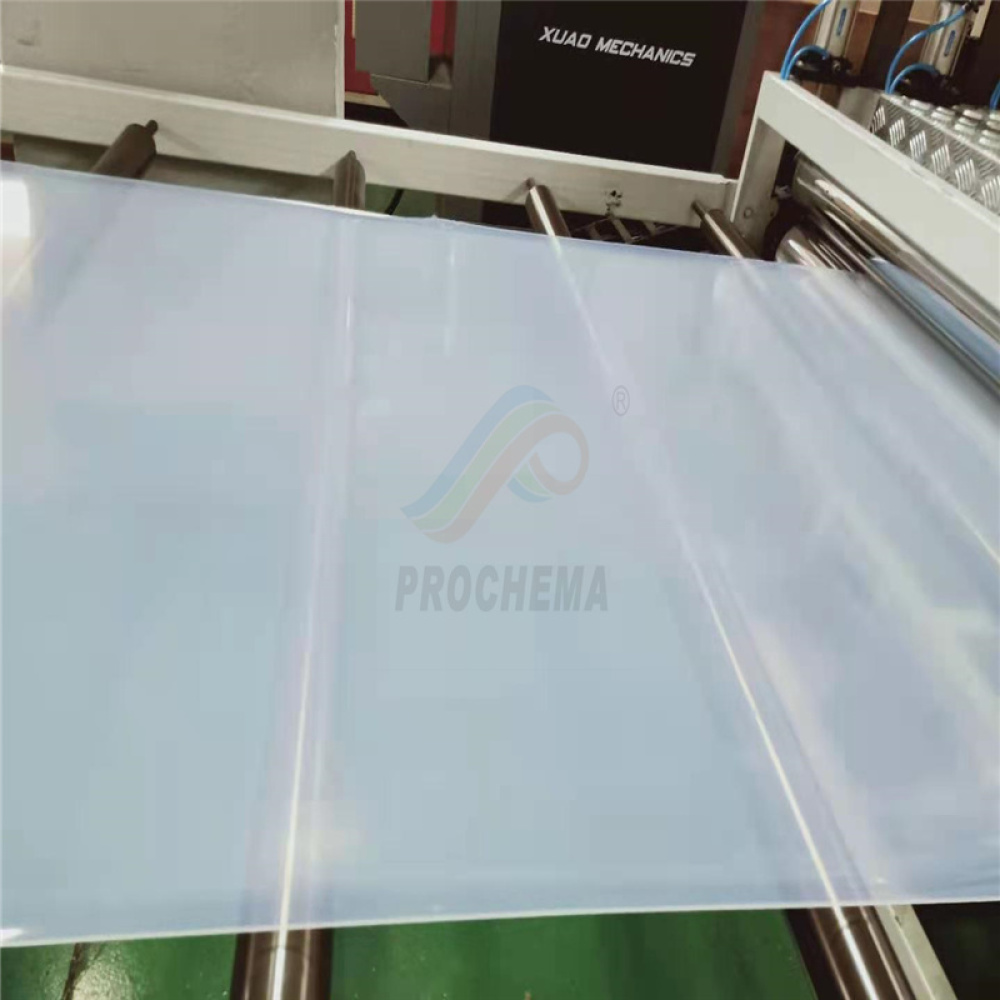

Chinese PFA Extrusion Anticorrosive Lining sheet

Thickness 1.5 2 2.3 3..4..5. 6mm width 1000-1500mm

Producing method:Extrusion

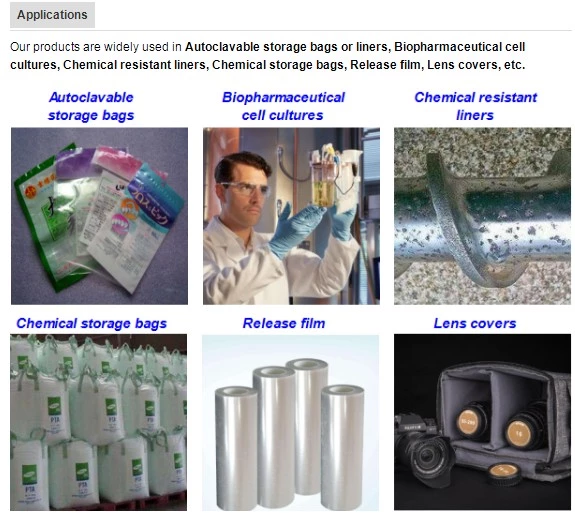

Application: Anticorrosive lining

PFA Sheet is made from PFA resin and prepared by the technology of thermoplastic extrusion and blowing.

It has non-sticking, heat-resistance, aging resistance, corrosive resistance, non-flammability and good electric property. It

can be solid adhesive for PTFE and also a good adhesive for laminating various materials. Its working temperature is up to 260 and is an ideal material for circuit board and flat cable.

Introduction:

PFA is a copolymer of tetrafluoroethylene and perfluoroalkyl vinylether. It is a perfluoro polymer consisting of only carbon atoms and fluorine atoms without any hydrogen atom.

Properties :

High low temperature resistance:

-200--260°C,high temperature strength is 2 times higher than PTFE

Good adhesive and heat sealability with PTFE:

Below melting point ,it won’t stick any project.Above melting point, it has perfect adhesive property with PTFE, Metal and

self-adhesion(heat sealing).

None stick to water ,oil : water contact angle: θ=115o

Electric reliability,High dielectric

60HZ-60MHZ , Under the high and low temperature,the permittivity keeps 2.1 even if the surface damaged ,it won’t has conductive track.

Volume resistance>1018ΩM

Surface resistance>2*1013Ω

Voltaic Arc Resistance >165s No electric leakage

Weather resistance: It can be used in sunlight and ozone long

Anti-corrosion :Only in high temperature, Fluorin and alkalis can effect it,others acid, alkali or ester won’t effect it.

Fireproof : If firing, and will still insulate .

High diaphaneity

UL-Resistance : Good penetrability in ultraviolet radiation,and lowest refraction coefficient

|

Item

|

Value

|

|

|

|

General purpose

|

electric purpose

|

|

Density g/cm3

|

2.12-2.17

|

2.12-2.17

|

|

Temperature range °C

|

-200 -+260

|

-200-+260

|

|

Longi&tray,shrink rate % ≤

|

3.0

|

3.0

|

|

Tensile strength Mpa ≥

|

14

|

14

|

|

Elongation at break % ≤

|

175

|

175

|

|

Elongation at break % ≤

|

4.9x104

|

4.9x104

|

|

Dielectric Constanct (106Hz)

|

|

2.15

|

|

Dissipation Factor 106Hz ≤

|

|

1x10-3

|

|

Volume resistance (Ω.m)

|

|

1x1014

|

|

Dielectric Strength TH ≤ 0.05mm

Th 0.05-0.1mm M/V TH ≥ 0.1mm |

|

100

75

50

|

|

|

|

|

|

|

|

|

Q: What's your supportive policy for distributors in overseas market?

A:We support in many aspects including marketing, promotion, product developmentimprovements