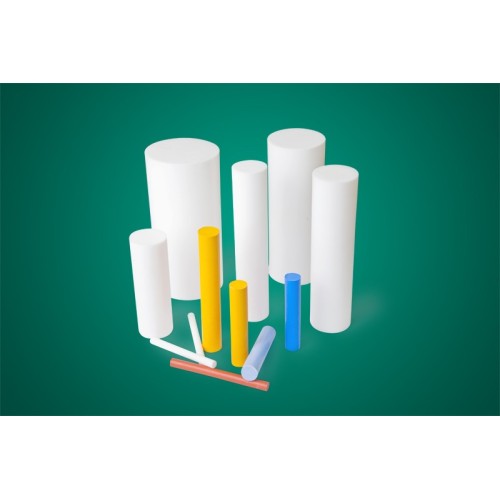

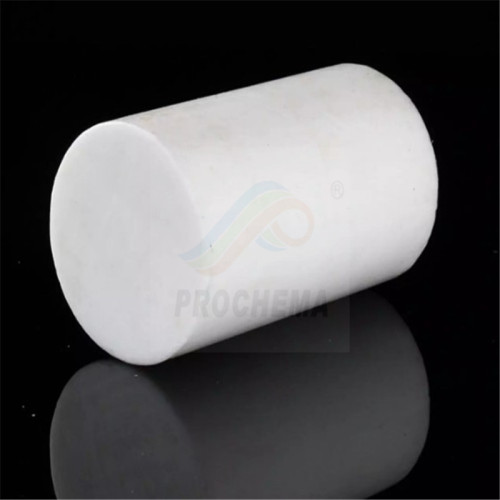

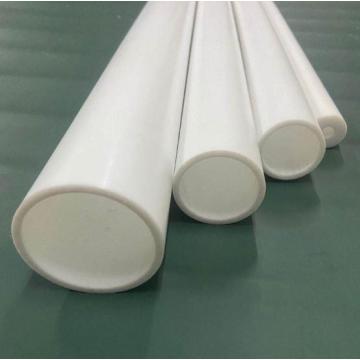

Ptfe Non-stick Anticorrosive Insulative Rod

Ptfe rod is a kind of suitable for processing all kinds of work in corrosion medium liner, seal and lubrication materials, and used under various frequency electrical insulating parts without filled ptfe resin (can be regenerated polytetrafluoroethylene resin) by moulding, paste extrusion or plunger extrusion process molding bar.

Ptfe bar has two kinds of pushing bar and moulded bar. Ptfe bar has the best chemical corrosion resistance and dielectric property in known plastics, can be used at -180℃-+260℃ temperature, and has the lowest friction coefficient. It is mainly suitable for some long products and non-standard mechanical parts.

Tetrafluoroethylene rod: Tetrafluoroethylene rod is divided into two types: molding rod and extrusion rod. Molding rod is made of polytetrafluoroethylene resin and molded by molding method at room temperature, and then sintered and cooled. The extruder rod is made of polytetrafluoroethylene resin by drying, breaking and high temperature extruder.

Features: high temperature resistance up to 250℃, low temperature resistance -196℃, corrosion resistance, climate resistance, high lubrication, non-adhesion and other characteristics.

Outstanding properties: Tetrafluoroethylene is almost impervious to any chemical corrosion except molten alkali metal. For example, in concentrated sulfuric acid, nitric acid, hydrochloric acid, or even boiling in aqua, its weight and performance are unchanged, and almost insoluble in all solvents.

PTFE MODIFIED ROD :

The fillers used for PTFE modification can be inorganic materials, organic materials, metals and metal oxides. Inorganic materials include: glass fiber, graphite, molybdenum disulfide, carbon black, carbon fiber, ceramic powder, etc. Organics are mainly some high temperature resistant aromatic heterocyclic polymers, including PEEK, PPS and so on. These organic fillers can improve the surface properties of blends such as wear, friction coefficient and surface tension. Metals and metal oxides used as fillers include copper powder, lead powder, and so on.

Features

1. Non-adhesion: almost all materials are not bonded with PTFE rod.

2, heat resistance: PTFE rod has excellent heat resistance and low temperature resistance characteristics. It can withstand high temperature to 300℃ in a short time, and can be used continuously between 240℃~260℃ in general, with significant thermal stability, it can work at the freezing temperature without embrittlement, and does not melt at high temperature.

3. Sliding property: PTFE rod has a low friction coefficient. The friction coefficient changes when the load slides, but the value is only between 0.05 and 0.15.

4, moisture resistance: PTFE coating surface does not touch water and oil, production operation is not easy to touch the solution, if there is a small amount of dirt, simply wipe can be removed. Short downtime saves time and improves work efficiency.

5. Wear resistance: excellent wear resistance under high load. Under a certain load, it has the dual advantages of wear resistance and non-adhesion.

6, corrosion resistance: PTFE is almost not subject to drug erosion, can withstand in addition to molten alkali metal, fluoride media and higher than 300℃ sodium hydroxide all strong acid (including aqua aqua), strong oxidant, reducing agent and various solvents, can protect parts from any kind of chemical corrosion.

Application :

PTFE rods are a combination of gaskets, sealants and smooth materials for processing in a variety of corrosive media. What are the advantages of PTFE bars in use, including electrical insulating parts used at various frequencies

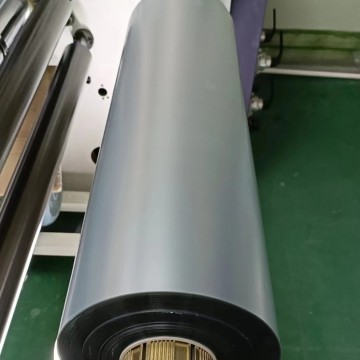

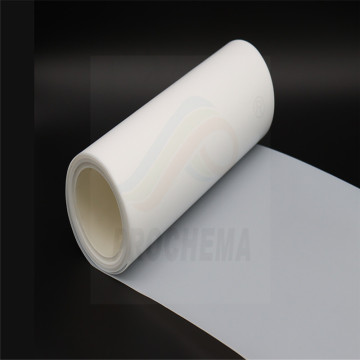

F4 bar application: PTFE bar can be pushed or extruded to form; For high temperature wire, it can also be made into a film and then cut into the shaft to install PTFE tape for the production of high frequency cable. It can be made directly into water dispersion liquid, which can be used for coating, impregnation or fiber.

Ptfe in atomic energy, defence, aerospace, electronics, electrical, chemical, machinery, instruments, meters, construction, textile, metal surface treatment, pharmaceutical, medical, food, metallurgical smelting and other industries widely used for high and low temperature resistance, corrosion resistant materials, insulation materials, anti-sticking coating, etc.

Used as anticorrosive material:

PTFE rod material overcomes the shortcomings of general plastics, metals and other non-corrosion resistant materials, and has become the primary corrosion resistant materials for petroleum, chemical and textile professions, such as the manufacture of transport pipes, exhaust pipes, steam pipes, etc. for the transport of corrosive gases

As an oil-free smooth material:

The friction coefficient of PTFE rod is low, so it is an ideal material for oil-free and smooth filling of mechanical equipment parts, such as papermaking, food, textile, etc. The addition of smooth oil can easily pollute the product. PTFE rod solves this problem.

High level dielectric materials for electronic equipment:

PTFE rods inherent in the dielectric constant and low loss makes it the wire and cable insulation materials, its porous structure can make the loss and distortion dropped to a lower, and a hot not disorderly and must be flexible, PTFE rods is still a prominent filling medium material, widely used in the category of computer, national defense and so on many challenging.

Used as anti-stick material:

PTFE bar with its inherent low surface tension, does not adhere to any substances, but also has high and low temperature resistance, non-toxic good properties, PTFE bar is primarily used in non-stick pan and microwave oven liner.

Used as medical materials:

PTFE rod has good mechanical function, durability and biological adaptability, which will not cause body reaction and has no side effects on human physiology. Moreover, PTFE rod has the characteristics of multi-pore structure, which is increasingly widely used in medicine. These include artificial blood vessels and patches for soft tissue regeneration, and surgical sutures for blood vessels, hearts, general surgery, and plastic surgery.

PROPERTIES:

|

Item

|

Unit

|

Data

|

|

Density

|

g/cm3

|

2.1-2.3

|

|

bending strength

|

Mpa

|

11-14

|

|

tensile strength

|

MPa

|

21-28

|

|

elongation at break

|

%

|

≥200

|

|

friction coefficient

|

/

|

0.04

|

|

water absorption

|

%

|

<19

|

|

dielectric strength

|

KV/mm

|

18

|

|

operating temperature

|

℃

|

-180-260

|

|

melting temperature

|

℃

|

325

|

Specification :

Moulded rod: Dia8-500mm X Length 100-200mm

Extrusion rod:Dia5-170mm xLength 1000mm