-

$19.00≥100 Kilogram

Business type:Manufacturer,Trade Company,Distributor/Wholesaler

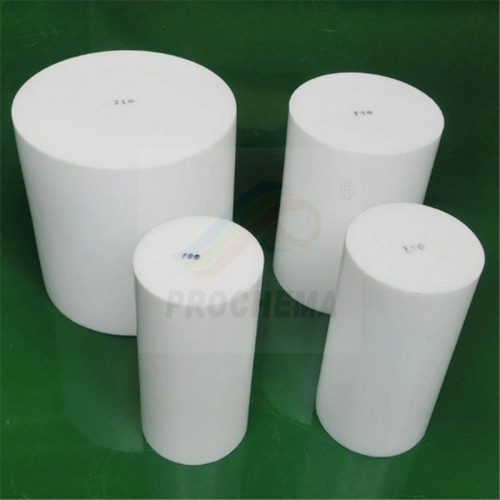

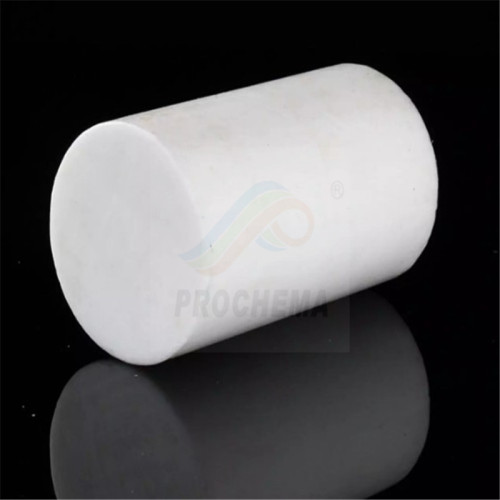

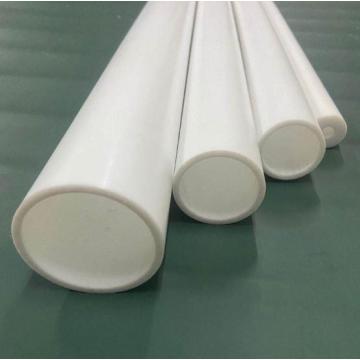

PTFE Compress-Proof Wear Resistance BaSO4 Rod

PTFE rod can be manufactured by three kinds of process. The rod can be made by paste extruded, plug extruded, and molded

Increases compressive strength, hardness and wear resistance Reduces creepPtfe rod is a kind of suitable for processing all kinds of work in corrosion medium liner, seal and lubrication materials, and used under various frequency electrical insulating parts without filled ptfe resin (can be regenerated polytetrafluoroethylene resin) by moulding, paste extrusion or plunger extrusion process molding bar.

Tetrafluoroethylene rod: Tetrafluoroethylene rod is divided into two types: molding rod and extrusion rod. Molding rod is made of polytetrafluoroethylene resin and molded by molding method at room temperature, and then sintered and cooled. The extruder rod is made of polytetrafluoroethylene resin by drying, breaking and high temperature extruder.

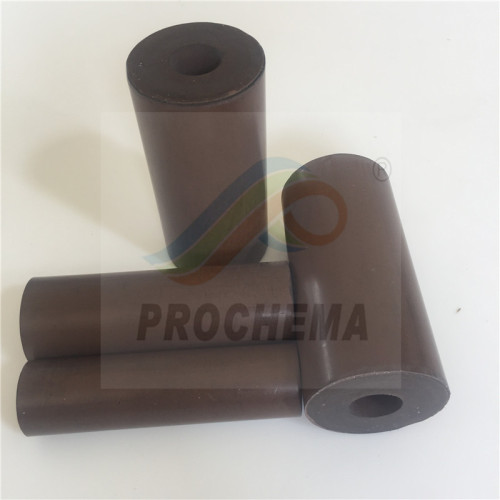

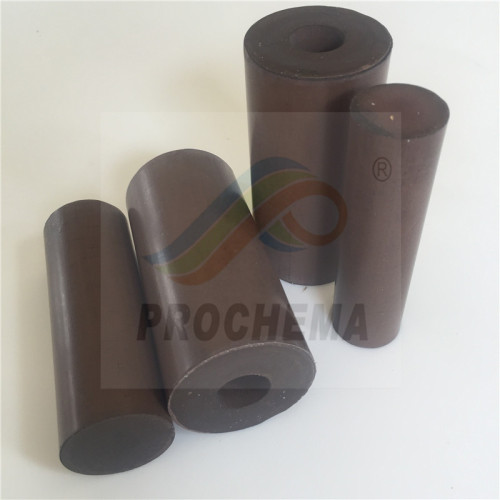

PTFE MODIFIED ROD :

The fillers used for PTFE modification can be inorganic materials, organic materials, metals and metal oxides. Inorganic materials include: glass fiber, graphite, molybdenum disulfide, carbon black, carbon fiber, ceramic powder, etc. Organics are mainly some high temperature resistant aromatic heterocyclic polymers, including PEEK, PPS and so on. These organic fillers can improve the surface properties of blends such as wear, friction coefficient and surface tension. Metals and metal oxides used as fillers include copper powder, lead powder, and so on.

Features

Application :

F4 bar application: PTFE bar can be pushed or extruded to form; For high temperature wire, it can also be made into a film and then cut into the shaft to install PTFE tape for the production of high frequency cable. It can be made directly into water dispersion liquid, which can be used for coating, impregnation or fiber.

As an oil-free smooth material:

PROPERTIES:

|

Item |

Unit | Data |

| Density |

g/cm3 |

2.1-2.3 |

|

bending strength |

Mpa |

11-14 |

|

tensile strength |

MPa |

21-28 |

|

elongation at break |

% |

≥200 |

|

friction coefficient |

/ |

0.04 |

|

water absorption |

% |

<19 |

|

dielectric strength |

KV/mm |

18 |

|

operating temperature |

℃ |

-180-260 |

|

melting temperature |

℃ |

325 |

PTFE filled with other materials:

|

Filled materials |

Common filled ratio ( Quantity %) |

Main performances |

|

Bronze |

40, 60 |

Increases hardness and wear resistance; |

|

Carbon |

5, 10, 15 |

Increases compressive strength, hardness, wear, and load properties. |

|

Graphite |

5, 10, 15 |

Improves the deformation under load; Reduces initial wear; |

|

Glass Fiber |

10, 15, 25 |

Increases compressive strength, rigidity and wear. |

|

Carbon Fiber |

10 , 15, 25 |

Increases compressive strength, hardness, wear, and load properties. |

|

POB |

5, 10, 15 |

Improve the lubrication performance;Enhance the mechanical strength; Increase using temperature |

|

BaSO4 |

5, 10, 15 |

Increases compressive strength, hardness and wear resistance |

|

SiO2 |

5, 10, 15 |

Increases hardness and wear resistance; Improve Dimensional Stability. |

|

Glass beads |

5, 10, 15 |

Reduces creep and cold flow;Lower density |

|

Others materials |

PEEK(polyetheretherketone), PI(Polyimide), MoS2 are also ok |

|

|

Remarks |

Some materials have similar enhancement effect, but degrees of enhancement are different. And they have different prices. More details please contact us. |

|

Specification :

he Specification of PTFE Rod

|

Dia(mm) |

Length(mm) |

Length(mm) |

|

1, 2, 3, 4 |

continuous length |

|

|

5, 6, 8, 10, 12, 15, 16, 18, 20, 22, 25, 28, 30, 32, 35, 40 |

1000 |

2000 |

|

45, 50, 55, 60, 65, 70, 75, 80, 85, 90, 95, 100 |

1000 |

2000 |

|

110, 120, 130, 140, 150, 160, 170, 180, 190, 200 |

1000 |

2000 |

|

210, 220, 230, 240, 250, 260, 270, 280, 300 |

300 |

|

|

310, 320, 330, 340, 350, 360, 370, 380, 390, 400, 410, 420, 440, 450, 460, 470, 480, 490, 500 |

100 |

|

Q: What's your supportive policy for distributors in overseas market?

A:We support in many aspects including marketing, promotion, product developmentimprovements