Chinese 3m PTFE TFM 1600 Microwave digestion tank

PTFE TFM Digestion Tank TFM Dissolution Tank

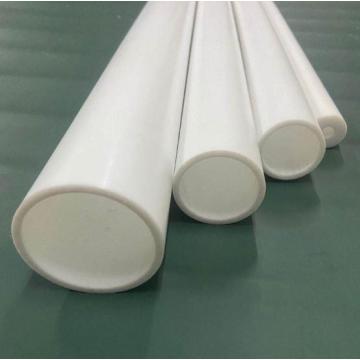

Name: microwave digestion tube

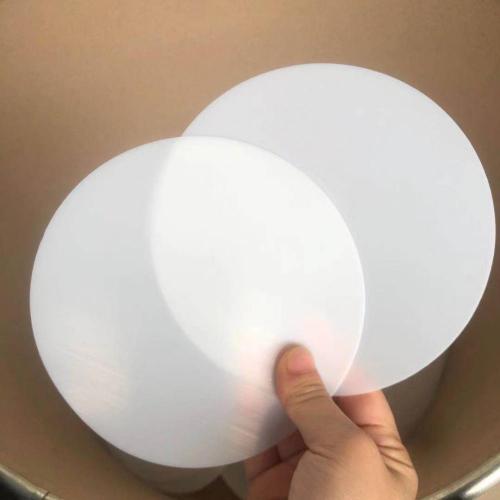

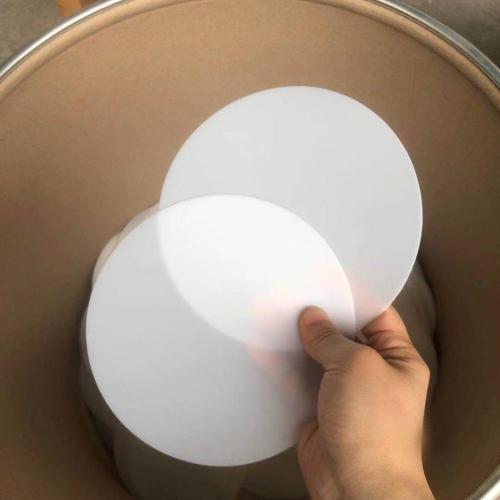

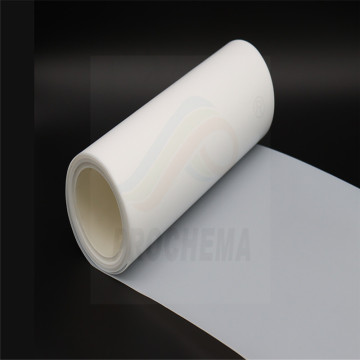

Material: PTFE/imported TFM material

Color: white

Polytetrafluoroethylene microwave digestion tank, also known as (perfluorine digestion tank, perfluorine dissolution tank, digestion tank, dissolution tank) microwave oven, microwave digestion instrument used, easy to clean, not rust.

Polytetrafluoroethylene microwave digestion tank main technical parameters:

1, working temperature: ≤220℃

2. Working pressure: ≤ 0.3Mpa

Characteristics of perfluorine microwave digestion tank: the digestion tank is easy to operate, safe and reliable, firm and durable. Made of acid-resistant (hydrochloric acid, nitric acid, aqua regia, hydrofluoric acid, etc.) and alkali of total polytetrafluoroethylene, good chemical stability. The material is pure and does not contaminate the determination of trace elements. Can be used for industry, agriculture, environmental protection, health inspection, metallurgy, geology, medicine, chemical industry and other departments of all kinds of sample digestion.

Strong digestion ability, even for difficult to dissolve high temperature alloy steel, rutile, platinum rhodium catalyst, etc., can be quickly completely decompose. Fast digestion. Generally, the sample only needs 3-5 minutes to be completely digested

PTFE /PTFE using imported PTFE powder after high temperature thermoplastic molding, and then through automatic lathe precision processing made, capacity 50ml 100ml high temperature resistance, strong acid resistance.

1. Pure white appearance

2. High temperature resistance: use temperature -200 ~ +250℃; Short-term electric heating plate can withstand 300℃, open fire heating needs to be used in asbestos net.

3. Low temperature resistance: -196℃ can maintain 5%;

4 corrosion resistance: has extraordinary chemical resistance, almost can tolerate all chemical solvents (resistance to strong acid, strong alkali, aqua regia and various organic solvents);

5. Insulation resistance: dielectric performance is independent of temperature and frequency;

6. High lubrication: the friction coefficient of solid materials (0.04) at the bottom;

7. Non-adhesion: does not adhere to any substance; Non-toxic;

8. Pollution prevention: low blank value of metal elements, less than 10-11 g/ml lead content, less than 10-12 g/ml uranium content

Characteristics of perfluorinated microwave digestion tank:

Microwave digestion tank is made of polytetrafluoroethylene, resistant to strong acid, strong alkali, strong corrosion, etc.

Beautiful appearance, reasonable structure, simple operation, shorten the analysis time, reliable data.

It can replace platinum crucible to solve the problem of sample dissolution for analysis of trace elements in high purity alumina.

Leakproof: when falling from 1.2 meters above the ground, the bottle body does not break, the cap does not fall off, and there is no damage and leakage phenomenon.

Product design: there is overpressure self-release hole, safe to use. After rising temperature and increasing pressure, the samples which are difficult to be dissolved under conventional conditions and those containing volatile elements can be dissolved rapidly and without damage. With minimal pollution and low reagent blank, it is favorable for the accurate determination of trace elements by high sensitivity analytical instrument.

This product is made of experimental high purity and high quality polytetrafluoroethylene material, with better temperature resistance, stable quality and low blank value, which greatly improves the accuracy and precision of analysis and reduces the working time.

Note: When the digestion tank is heated by oven, microwave or electric heating plate, the lid should not be completely tightened and locked to prevent explosion caused by high pressure of gas. Please bear in mind.

PTFE/TFM microwave digestion tank

PTFE/TFM microwave digestion tank is a customized product, can be customized according to customer requirements, the tank material adopts high purity PTFE/TFM material integrated milling and washing molding, the tank thickness is uniform, the inner wall is smooth, no wall hanging, heating is not bent, fully meet the requirements of experimental use

This product has fewer structural components, easy operation, safe and reliable, firm and durable. Safety protection with explosion-proof pad. Made of acid-resistant (hydrochloric acid, nitric acid, aqua regia, hydrofluoric acid, etc.), alkali of total polytetrafluoroethylene, good chemical stability, can resist the temperature below 200℃. The material is pure and does not contaminate the determination of trace elements. Can be used for industry, agriculture, environmental protection, health inspection, metallurgy, geology, medicine, chemical industry and other departments of a variety of sample digestion; It is especially suitable for the accurate determination of trace, trace and ultra-trace elements in various samples by atomic spectroscopy, such as atomic absorption meter, ICP-emission spectrometer, atomic fluorescence meter, ICP-mass spectrometer, and anodic stripping meter. The digester can only be equipped with a household microwave oven for digestion of various samples to achieve the following effects:

(1) Strong digestion ability. Even for the refractory high temperature alloy steel, rutile, platinum rhodium catalyst, can be quickly completely decompose.

(2) Fast digestion speed. Generally, the sample only needs 3-5 minutes to be completely digested.

(3) Less reagent consumption. Usually only 3-5 ml of solvent is needed, especially saving high purity reagents, greatly reducing the cost of analysis.

(4) minimal pollution, low reagent blank, is conducive to the high sensitivity analysis instrument accurate determination of trace elements.

(5) Save energy and use less electricity.

(6) Less one-time investment cost.

(7) Material: PTFE.

(8) Pressure: 0.7-1Mpa.

Application:

Digestion tank is used for sample pretreatment and dissolution in gas phase, liquid phase, plasma mass spectrometry, atomic absorption and other chemical analysis methods.

Specification:

|

Volume

|

tube body OD

|

Tube mouth ID

|

tube height

|

Total height with lid

|

|

30ml

|

38mm

|

24mm

|

90mm

|

116mm

|

|

50ml

|

47mm

|

30mm

|

85mm

|

113mm

|

|

60ml

|

47mm

|

31mm

|

100mm

|

127mm

|

|

100ml

|

57mm

|

39mm

|

105mm

|

138mm

|

|

200ml

|

70mm

|

49mm

|

130mm

|

165mm

|

|

customised

|

customised

|

customised

|

customised

|

Customised

|