-

$10.00≥200 Roll

Business type:Manufacturer,Trade Company,Distributor/Wholesaler

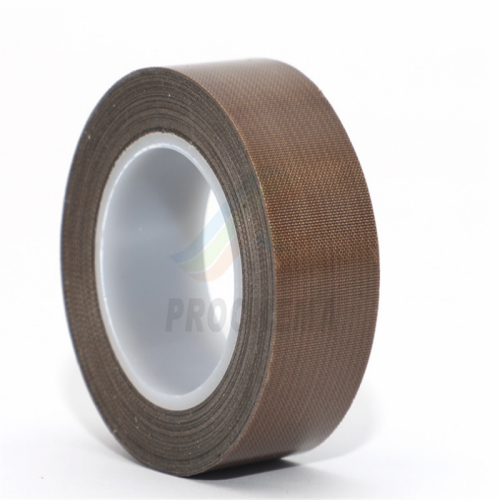

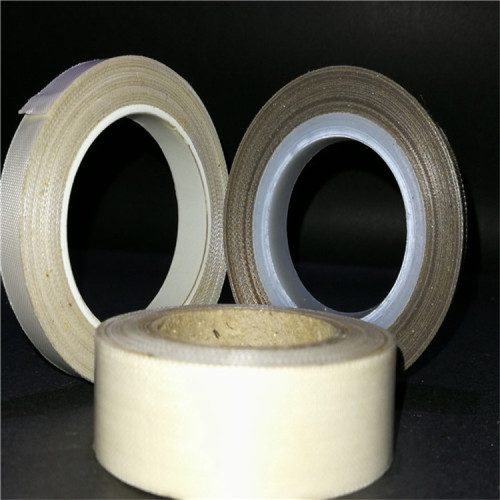

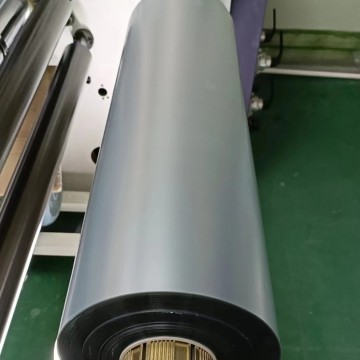

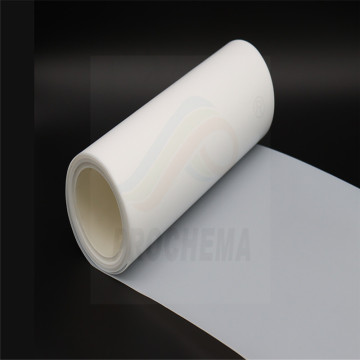

PTFE Coated Fiberglass Fabric Silicone Adhesive Tape

PTFE high temperature adhesive tape High temperature resistant special wire and cable pipeline repair corrosion resistant waterproof sealing tape adhesive tape

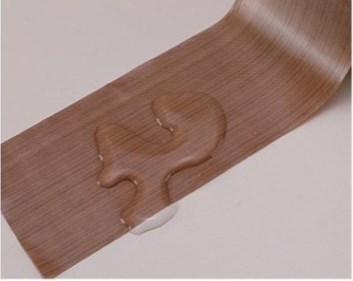

PTFE coated fiberglass one side silicone pressure sensitive adhesive tapes for temperature reisstance up to 260 centigrade. This tape are used in sealing of polymer film in FFS, Impluse sealer, Band Sealer and Bags making machine. During this operation is made more efficient, if the sealing bars are convered with the strips of the ptfe coated fiberglass fabric and ptfe coated fibergalss fabric one side adhesive, which is a very good heat conductor and gives non stick surface.

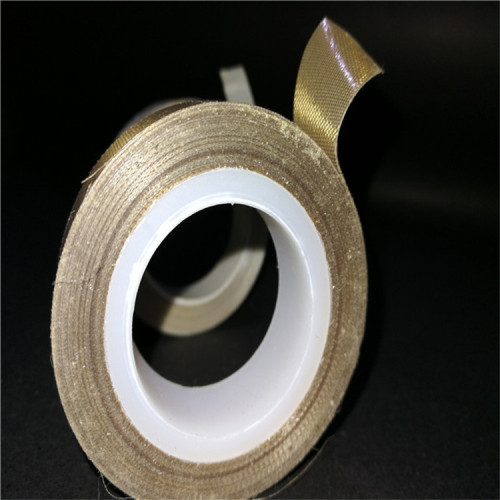

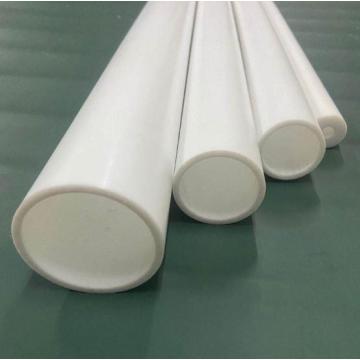

F4 PTFE Tape ( H-Class ) Type M-PTFEC, This product is PTFE resin the agglutination reaction coagulates under the extremely huge pressure in the high temperature environment. In a lathe rotation situation next processing, Cutter The cent slice。F4 self-sticking tape have comparatively high abilities of oil resisting,temperature resisting and electricity insulating , and are applied for covering the junctions of the cables of the electrical machinery on the deep oil wells and the high temperature cable junctions , other electrical machines including electrical motors and appliances. Widely applies in the aviation, the navigation, the military insulates ,Also the new material , most advanced technique domain.

Main Features of High Temperature Resistant Adhesive PTFE Tape:

- Chemical resistance

- Wear resistance

- High temperature resistance

- High strength

- Excellent electrical insulation properties

- Good thermal conductivity;

- Easy fit and no adhesive residue

Application range of High Temperature Resistant Adhesive PTFE Tape:

1.For molding: mold-releasing sheets.

2.For printing: drying screen-printing machines.

3.For apparels: adhesive interlining belts.

4.For food processing: heat sealers, frozen food transportation, defrosting belt and baking belt.

5.For packing: shrink film packaging and side band sealing.

-Easy release surface for heat sealing and packaging machines;

- Ironing and pressing equipment;

- Covering drying cylinders;

- Lining chutes, release surface on bonding tools;

- PVC welding release fabric.

|

Properties |

Unit |

Standard Value |

Test Value |

Standard Value |

|

F4 film Thickness |

mm |

0.12 ± 0.010 |

0.124 |

0.080 ± 0.010 |

|

Width |

mm |

25. 0 ± 1.0 |

25.02 |

0 - 150 |

|

|

|

25.4 ± 1.0 |

25.42 |

|

|

Tensile strength |

N/25mm Width |

≥ 88.0 Longitudinal direction |

115.3 Longitudinal direction |

≥ 60.0 Longitudinal direction |

|

Elongation rate |

% |

≥ 150 Longitudinal direction |

215.0 Longitudinal direction |

≥ 150 Longitudinal direction |

|

Breakdown voltage |

KV |

≥ 10 |

13.5 |

≥ 7 |

|

Temperature |

℃ |

≥ 180 |

||

|

Additional: |

|

Width ≤150 mm |

Storage life: 12months (below40℃) |

|

|

Unit length |

meter |

Unit length according to customer request design processing |

||

|

Product name

|

PTFE tape

|

|

Material

|

Glass fiber cloth

|

|

Adhesive

|

Silicone

|

|

Thickness

|

0.13mm / 0.18mm/0.25mm

|

|

Width

|

10//13/19/25/30/38/50mm or customized

|

|

Length

|

10m ,30m , 50m

|

|

Temperature resistance

|

-70℃- 300℃

|

|

Tensile strength

|

1700N/100mm

|

|

Adhesion to steel

|

28N/100mm~74N/100mm

|

|

Insulation

|

≥10¹² Ω

|

|

Friction coefficient

|

0.05-0.1

|

|

Application

|

Heat sealing of food, vacuum sealer, pharmaceuticals and packaging, various mechanical rollers requiring anti-adhesion, corrosion resistance and high temperature resistance.

|

* Non-stick.

* Good insulation.

* Anti-static, UV-proof, fire-retardant.

* Chemical corrosion resistant.

* Non-toxic.

* Stable and durable.

Q: What's your supportive policy for distributors in overseas market?

A:We support in many aspects including marketing, promotion, product developmentimprovements