-

$5.00≥2000 Square Meter

Business type:Manufacturer,Trade Company,Distributor/Wholesaler

PVDF anticorrosive weather fastness solar cell film

PVDF (polyvinylidene fluoride) is a kind of light fluoride material, with the working temperature ranging from -70 to 150 . It features superior corrosion resistance, mechanical property, electrical insulating property, low friction coefficient, weatherability, and radiation tolerance. Moreover, the tensile strength is two times higher than PTFE, the compressive strength six times higher than PTFE, and the abrasion resistance similar to nylon.

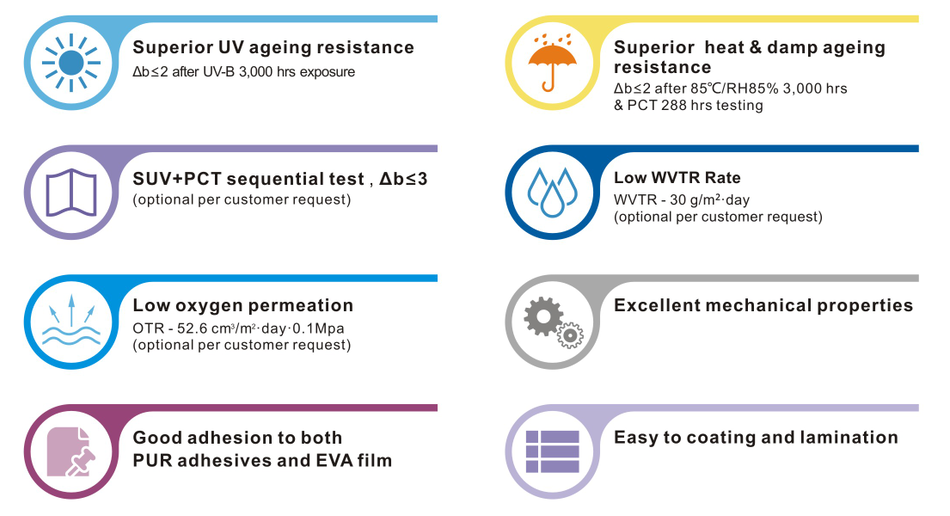

PVDF SOLAR CELL FILM is a pigmented Polyvinylidene Fluoride(PVDF) film product. The regular product is white colored without standing weathering resistance, including both UV-ageing and hydrolysis resistance. The white one is UV cut off, also featuring in low water and vapor transmission rate(WVTR). With single or double-side corona treated, the product provides a good adhesion to both PUR adhesives and EVA film. The film has a smooth surface with an excellent control in film gauge deviation, easily to coating and lamination. The film is normally used as a protect layer for Photovoltaic Backsheet, abbriviated as S” type. Due to its superior UV&Damp ageing performance, the product has over-25-year outdoor lifetime, providing a rigorous protection for photovoltaic backsheet. The film also can be used for non-photovoltaic applications, such as protect layer for colored metal plate or sheet, advertising light cases and other areas that need long-term resistance to light irradiation and outdoor weathering.

Product Specification

Length: 3,000m or longer

Width: 500~1,300mm

Thickness: 15~60μm

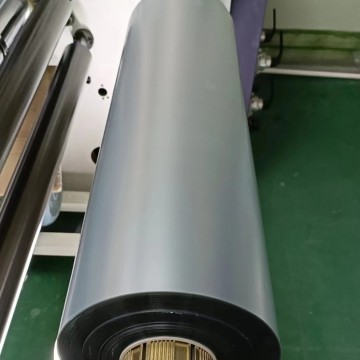

Color: White, Shallow Grey, Grey, Black, Shallow Blue and Sky Blue.

(Customized uponrequest, such as ultra-thin 12μm in thickness or ultra-wide up to 2,500mm in width)

PVDF Properties:

1. Flame retardancy

Application:

semiconductor, liquid crystal device, etc. Electronic industry field, chemical device field, food processing machine, packaging machine various parts, pipes, seals, pump parts, rotating disc, valve, slide track, etc. used for non-photovoltaic applications, such as protect layer for colored metal plate or sheet, advertising light cases and other areas that need long-term resistance to light irradiation and outdoor weathering.

Main applications of PVDF :

Main Performance

1, appearance: uniform texture, smooth surface; color was white.

2, the mechanical properties with the following table

|

Items |

unit |

Technical data |

|

Density |

g/cm3 |

2.122.17 |

|

Tensile strength |

Mpa |

≥35 |

|

Elongation at break |

% |

≥250 |

|

Hardness |

Shaw D hardness |

D70- D80 |

Q: What's your supportive policy for distributors in overseas market?

A:We support in many aspects including marketing, promotion, product developmentimprovements