>

<

The application of PVDF membrane in the aerospace field

Price:

-

$4.00≥5000 Square Meter

Mianyang Prochema Commercial Co.,Ltd.

22 YRS

Mianyang, Sichuan, China

Business type:Manufacturer,Trade Company,Distributor/Wholesaler

Close

Basic Info

Place of Origin

China

Productivity

500000m2

Supply Ability

500000m2/month

Payment Type

L/C,T/T,D/P,D/A,Paypal

Incoterm

Express Delivery,CFR,DAF,EXW,CIF,DES,FAS,FCA,CPT,CIP,DDP,DEQ,DDU

Certificate

ISO

Transportation

Ocean,Land,Air,Express

Port

shanghai,guangzhou,shenzhen

View All Details

Product Description

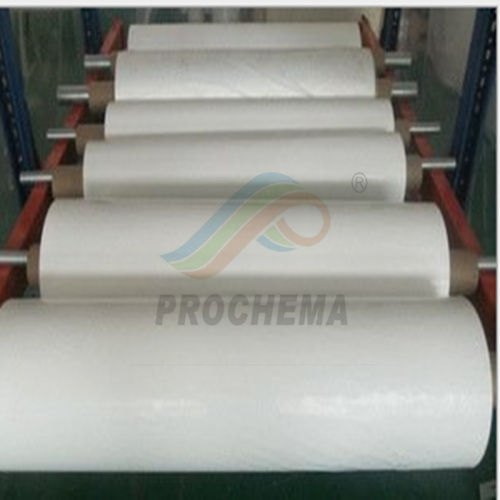

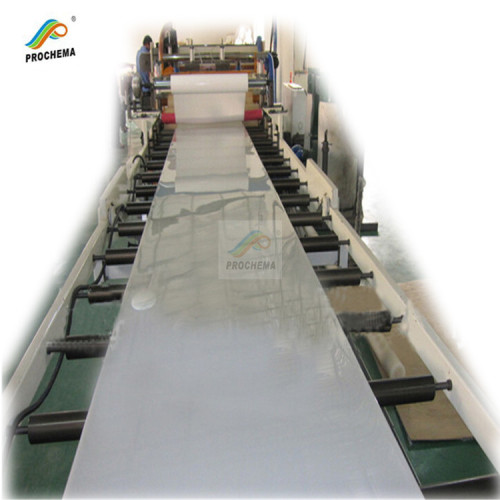

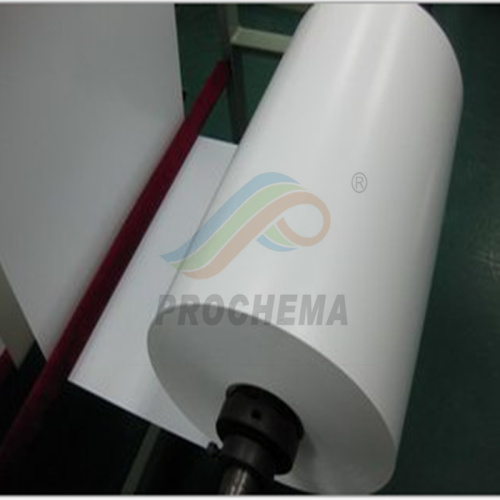

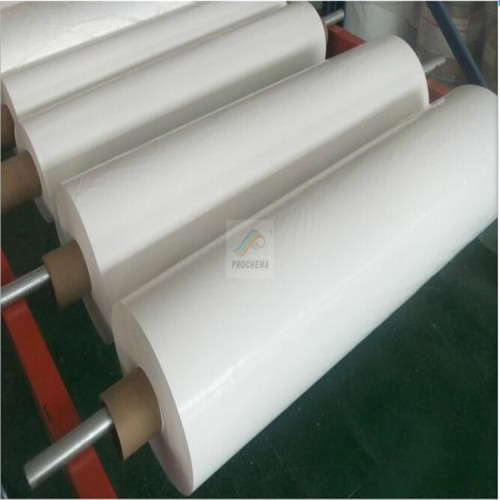

The application of PVDF membrane in the aerospace field

The application of PVDF membrane in the aerospace field refers to the utilization of Polyvinylidene fluoride (PVDF) membrane in aerospace technology or products. PVDF is a highly versatile material known for its durability, chemical resistance, and flexibility, making it suitable for various applications in the demanding environment of aerospace.

Some specific applications could include:

1. **Membrane Separation Processes**: PVDF membranes are used in gas separation processes, such as air separation units in aircraft engines or in the purification of gases used in spacecraft systems.

2. **Water Treatment Systems**: In aerospace, water treatment is crucial for maintaining the quality of drinking water and cooling systems. PVDF membranes are used in filtration systems to remove impurities from water.

3. **Electrochemical Applications**: PVDF's electrical properties make it useful in electrochemical applications, such as in batteries or fuel cells that power various aerospace components.

4. **Environmental Control Systems**: PVDF can be used in the construction of environmental control systems (ECS) on spacecraft, where it helps in filtering and conditioning the cabin atmosphere.

5. **Structural Components**: While not typically the primary structural material, PVDF can be used in lightweight, high-strength composite materials for certain aerospace applications due to its excellent mechanical properties.

6. **Coatings and Insulation**: PVDF-based coatings offer superior resistance to corrosion and UV degradation, making them suitable for protective coatings on aerospace structures.

7. **Microfluidic Devices**: In advanced aerospace research and development, microfluidic devices made with PVDF can be used for precise handling and analysis of small samples.

8. **Pressure Sensors and Actuators**: PVDF's piezoelectric properties can be utilized in the fabrication of pressure sensors and actuators that are critical for monitoring and controlling various systems within an aircraft or spacecraft.

These applications demonstrate the diverse and essential role of PVDF membranes in advancing and sustaining modern aerospace technologies.

Some specific applications could include:

1. **Membrane Separation Processes**: PVDF membranes are used in gas separation processes, such as air separation units in aircraft engines or in the purification of gases used in spacecraft systems.

2. **Water Treatment Systems**: In aerospace, water treatment is crucial for maintaining the quality of drinking water and cooling systems. PVDF membranes are used in filtration systems to remove impurities from water.

3. **Electrochemical Applications**: PVDF's electrical properties make it useful in electrochemical applications, such as in batteries or fuel cells that power various aerospace components.

4. **Environmental Control Systems**: PVDF can be used in the construction of environmental control systems (ECS) on spacecraft, where it helps in filtering and conditioning the cabin atmosphere.

5. **Structural Components**: While not typically the primary structural material, PVDF can be used in lightweight, high-strength composite materials for certain aerospace applications due to its excellent mechanical properties.

6. **Coatings and Insulation**: PVDF-based coatings offer superior resistance to corrosion and UV degradation, making them suitable for protective coatings on aerospace structures.

7. **Microfluidic Devices**: In advanced aerospace research and development, microfluidic devices made with PVDF can be used for precise handling and analysis of small samples.

8. **Pressure Sensors and Actuators**: PVDF's piezoelectric properties can be utilized in the fabrication of pressure sensors and actuators that are critical for monitoring and controlling various systems within an aircraft or spacecraft.

These applications demonstrate the diverse and essential role of PVDF membranes in advancing and sustaining modern aerospace technologies.

Q: What's your supportive policy for distributors in overseas market?

A:We support in many aspects including marketing, promotion, product developmentimprovements

You May Also LikeRelated Keywords

You May Also Like

>

<

Other popular products

>

<

Contact Now